In today’s fast-paced economy, freight management is more than just moving goods from point A to point B. It’s about creating a seamless, efficient, and cost-effective supply chain that enhances customer satisfaction and drives business success. Companies that master freight management gain a significant competitive advantage, ensuring timely deliveries, reducing costs, and maintaining flexibility in the face of market changes.

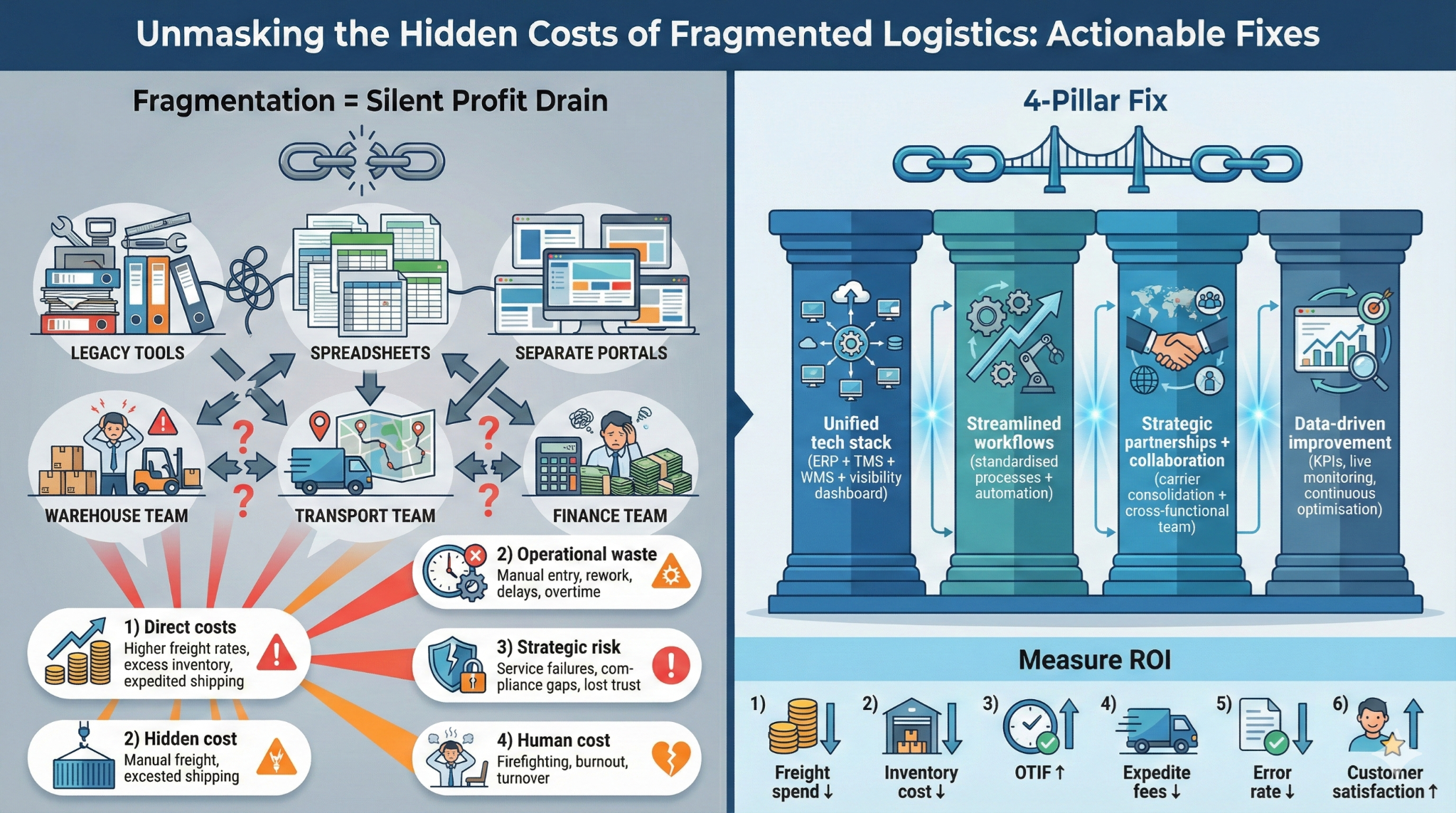

But what does smart freight management look like? It’s built on five key pillars: visibility, cost optimisation, carrier performance, risk management, and continuous improvement.

-

Visibility: The Power of Real-Time Tracking

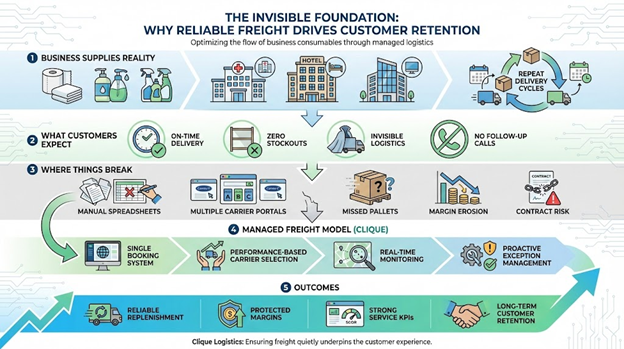

Gone are the days of blindly waiting for shipments. Real-time tracking technology enables businesses to monitor freight movements at every stage, providing crucial data for proactive decision-making. With increased visibility, businesses can anticipate delays, adjust schedules, and keep customers informed—enhancing overall service reliability.

Implementing transportation management systems (TMS) and integrating them with supply chain networks allows businesses to track shipments, analyse performance metrics, and make data-driven improvements. This level of insight is invaluable for reducing inefficiencies and ensuring smooth operations.

-

Cost Optimisation: Balancing Price and Value

While it’s tempting to choose the cheapest freight options, smart logistics management focuses on optimising costs rather than just cutting them. This means evaluating the total cost of ownership (TCO), which includes factors such as transit times, damage rates, and reliability.

Choosing a provider with a proven track record of efficiency and customer service often leads to long-term savings, reducing unexpected costs from delays, damage claims, and inefficiencies. Leveraging bulk shipping discounts, consolidating shipments, and negotiating strategic contracts with carriers are all methods to enhance cost optimisation.

-

Carrier Performance: Selecting the Right Partners

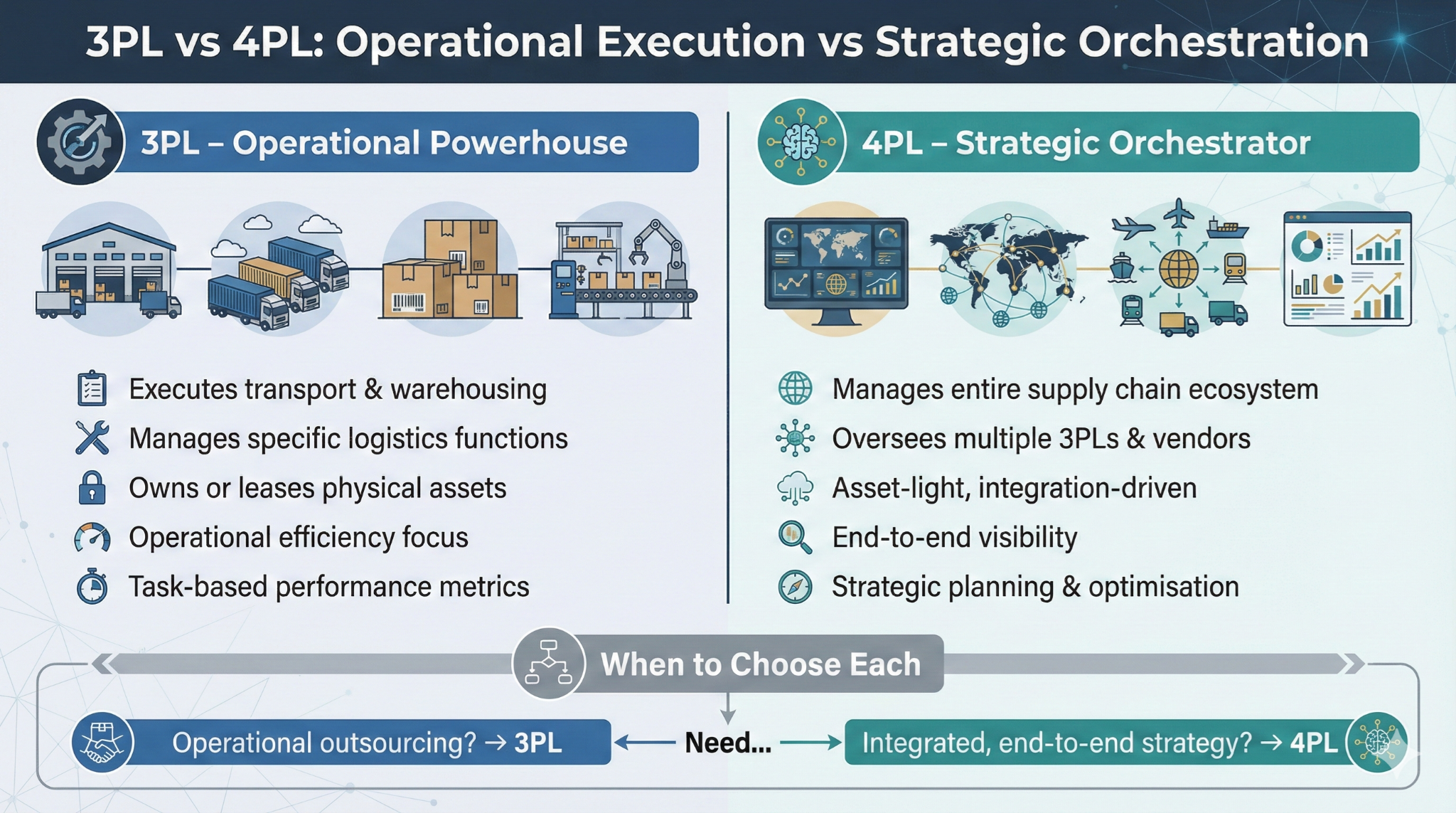

Not all carriers are created equal. Evaluating carrier performance is essential to maintaining a smooth logistics operation. Companies must assess criteria such as on-time delivery rates, handling of goods, communication, and flexibility to determine which carriers align best with their needs.

Multi-carrier strategies also help mitigate risks by ensuring businesses aren’t overly reliant on a single provider. Instead, having a mix of regional and national carriers can optimise service levels and costs while improving overall network resilience.

-

Risk Management: Preparing for the Unexpected

Freight management is inherently unpredictable. From weather disruptions to carrier capacity shortages, businesses must have contingency plans in place. Risk mitigation strategies include diversifying carrier networks, securing cargo insurance, and implementing strong contractual agreements with logistics providers.

Additionally, regulatory compliance is an essential component of risk management. Staying ahead of industry regulations and ensuring all partners comply with safety and environmental standards helps avoid costly fines and reputational damage.

-

Continuous Improvement: The Key to Long-Term Success

Freight management is not a one-time setup—it’s an ongoing process. Companies that continuously analyse performance data, implement process improvements, and adopt new technologies will stay ahead of the competition.

Regular performance reviews, customer feedback integration, and investment in automation all contribute to more efficient logistics operations. By fostering a culture of continuous improvement, businesses can adapt to changing market conditions and drive sustained growth.

Conclusion

Mastering freight management requires a strategic approach that prioritizes visibility, cost optimisation, carrier performance, risk management, and continuous improvement. By focusing on these pillars, businesses can achieve seamless logistics operations that enhance efficiency, reduce costs, and improve customer satisfaction.