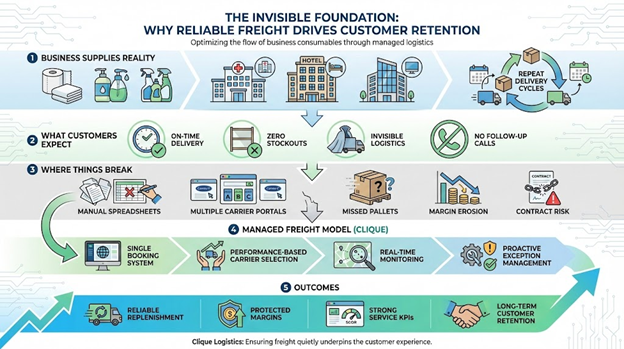

Choosing the right carriers is crucial for cost-effective, reliable, and scalable freight management. Many businesses make the mistake of relying on a single carrier, assuming it simplifies operations. However, this approach can lead to inefficiencies, lack of flexibility, and higher costs.

A multi-carrier strategy offers businesses greater resilience, competitive pricing, and improved service levels. Here’s why optimising your carrier network is essential—and how to do it effectively.

-

The Limitations of a One-Size-Fits-All Approach

Relying on a single carrier might seem convenient, but it often results in:

- Limited service options: No single carrier excels in all regions or freight types.

- Higher costs: A lack of competition can lead to pricing inflexibility.

- Capacity constraints: Carrier availability fluctuates, creating risks of delays.

- Increased risk exposure: If a carrier experiences delays, strikes, or financial struggles, your business is vulnerable.

By diversifying your carrier network, businesses can adapt to market changes, demand fluctuations, and evolving customer expectations.

-

Benefits of a Multi-Carrier Strategy

Optimising your carrier network brings several key advantages:

- Cost Savings: Different carriers offer competitive rates based on shipment size, destination, and urgency.

- Faster Deliveries: Multiple carrier options allow for more efficient routing and shorter transit times.

- Better Service Reliability: Redundancy reduces disruptions caused by carrier delays or failures.

- Enhanced Flexibility: The ability to match the right carrier to the right shipment improves efficiency.

- Stronger Negotiating Power: With multiple carriers, businesses can negotiate better rates and service agreements.

A well-balanced carrier network provides the best mix of cost, service quality, and speed.

-

Key Considerations for Carrier Selection

To build an optimal carrier network, businesses should evaluate carriers based on:

- Coverage & Network Strength: Ensure carriers serve key regions efficiently.

- Performance & Reliability: Assess on-time delivery rates and service consistency.

- Technology & Integration: Carriers should offer real-time tracking and data visibility.

- Cost & Pricing Models: Compare pricing structures, surcharges, and discounts.

- Sustainability Initiatives: Eco-friendly carriers can support corporate sustainability goals.

- Customer Service & Issue Resolution: Carriers with strong customer service can help quickly resolve shipping disruptions.

Selecting carriers strategically helps businesses align logistics with operational and customer needs.

-

Leveraging Data & Technology for Optimisation

Modern transportation management systems (TMS) enable businesses to manage multiple carriers seamlessly. These platforms help with:

- Automated Carrier Selection: Choose the most cost-effective and efficient carrier for each shipment.

- Route Optimisation: Identify the fastest and most economical delivery routes.

- Performance Analytics: Track carrier efficiency and adjust partnerships accordingly.

- Freight Spend Analysis: Identify cost-saving opportunities based on shipment patterns.

- Predictive Analytics: Anticipate potential disruptions and adjust shipments proactively.

By using data-driven insights, companies can refine their carrier strategy for continuous improvement.

-

Continuous Evaluation & Adaptation

Optimizing a carrier network isn’t a one-time task—it requires ongoing monitoring and adjustments. Regularly reviewing carrier performance, negotiating rates, and analysing shipping patterns ensures that the network remains efficient, cost-effective, and resilient. Companies should also keep an eye on emerging logistics trends, such as new shipping technologies and evolving customer expectations, to stay ahead of the competition.

Conclusion

A multi-carrier approach enhances cost savings, service quality, and operational flexibility. By leveraging data, technology, and strategic partnerships, businesses can create a robust and adaptable carrier network. Investing in a diverse carrier strategy not only reduces risk but also ensures long-term logistics success.