In today’s competitive business landscape, companies are looking for every possible opportunity to reduce costs and improve efficiency. Logistics, often one of the most significant operational expenses, presents a major opportunity for businesses to optimise their spend and maximise value. When done correctly, a well-planned logistics strategy can become a key competitive advantage, helping businesses not only reduce costs but also improve customer satisfaction and operational performance.

Here’s how businesses can extract maximum value from their logistics spend while ensuring it aligns with broader business goals.

1. Streamlining Operations through Automation

One of the easiest ways to reduce logistics costs while improving efficiency is to automate routine tasks. Automation helps to streamline key logistics functions such as inventory management, route planning, and order processing, significantly reducing human error and operational costs.

Benefits of automation in logistics:

- Reduced labour costs: By automating repetitive tasks, businesses can allocate human resources to more strategic areas.

- Faster processing times: Automation accelerates time-sensitive processes like order fulfillment and shipment tracking.

- Greater accuracy: Automation reduces the likelihood of errors in inventory management and order fulfilment, preventing costly mistakes.

By investing in the right technology—such as warehouse management systems (WMS) or transportation management systems (TMS)—businesses can achieve both operational savings and faster response times.

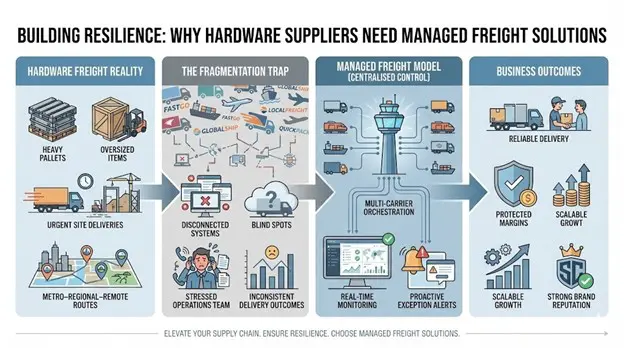

2. Optimising Freight Routes and Carrier Selection

Choosing the right carrier and optimising delivery routes is another critical factor in maximising logistics value. Businesses often make the mistake of focusing solely on the price of transportation when, in fact, the right carrier partnership can offer far more than just a low rate.

How to maximise freight value:

- Carrier diversification: Relying on a single carrier may limit flexibility and increase costs. By using multiple carriers, businesses can ensure they select the best option for each shipment based on delivery speed, reliability, and cost.

- Route optimisation: Real-time data and predictive analytics can help identify the most efficient shipping routes, reducing fuel costs and transit times.

- Negotiating better contracts: Understanding carrier performance and leveraging data allows businesses to negotiate better terms, including volume discounts or special service agreements.

By making informed decisions about which carriers to use and optimising routes, businesses can significantly reduce transportation costs while maintaining service quality.

3. Embracing Data-Driven Decision Making

In the digital age, data is a valuable asset for logistics management. Data analytics can provide deep insights into freight performance, customer demand, inventory levels, and potential disruptions, allowing businesses to make more informed, cost-effective decisions.

Key data-driven strategies include:

- Demand forecasting: Accurate forecasting enables businesses to plan shipments in advance, reducing the need for expedited (and expensive) deliveries.

- Real-time tracking: By monitoring shipments in real time, businesses can quickly respond to issues, avoid delays, and optimise delivery schedules.

- Performance analytics: Analyzing carrier performance and logistics trends helps businesses identify inefficiencies and opportunities for cost savings.

The right data analytics tools give businesses a clear view of their logistics operations, enabling them to adjust strategies in real time, thus reducing costs and improving efficiency.

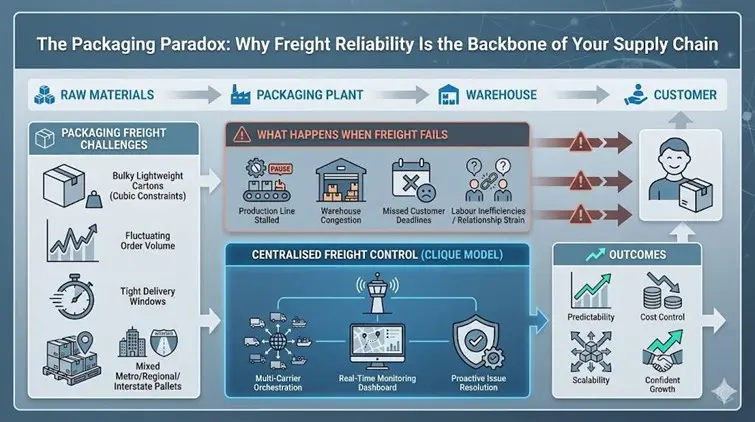

4. Improving Supply Chain Visibility

A transparent supply chain is one that allows businesses to track shipments, monitor inventory, and share information across stakeholders in real time. With enhanced visibility, companies can make smarter decisions and avoid costly disruptions.

How visibility enhances value:

- Better coordination: With real-time updates on shipments and inventory, businesses can coordinate better with suppliers, distributors, and customers.

- Faster response to issues: Visibility helps identify potential problems early, enabling businesses to take corrective action before delays or cost overruns occur.

- Informed decision-making: Having accurate, up-to-date data enables businesses to choose the best delivery options, negotiate better terms, and plan future logistics activities more effectively.

When companies implement supply chain visibility technologies, such as tracking systems and cloud-based platforms, they create a more agile and responsive logistics operation.

5. Collaborating with the Right Partners

Strategic partnerships are key to maximising the value of logistics. Rather than viewing logistics as an isolated function, businesses should treat their carriers, suppliers, and logistics providers as partners in the process. By developing strong, collaborative relationships, companies can negotiate better terms, optimise resources, and ensure more reliable delivery services.

How to build the right logistics partnerships:

- Open communication: Transparent and ongoing dialogue helps identify opportunities for cost savings and operational improvements.

- Shared goals: Aligning objectives—such as cost reductions, efficiency improvements, and customer satisfaction—ensures that both parties work toward the same outcomes.

- Long-term relationships: Building long-term partnerships creates stability, fostering a more reliable logistics network and the potential for ongoing discounts and improved service.

When businesses invest in fostering collaborative relationships, they can ensure more effective logistics strategies and long-term financial success.

Final Thoughts

Maximising value from every dollar spent on logistics isn’t just about cutting costs—it’s about investing in strategies that improve efficiency, customer satisfaction, and the overall performance of the supply chain. By automating operations, optimising freight routes, leveraging data, improving visibility, and forming strategic partnerships, businesses can turn logistics into a true competitive advantage.

In an increasingly complex and competitive market, the companies that can maximise the value of their logistics operations will be the ones that thrive in the long run.