In the fast-moving world of logistics, unforeseen disruptions can lead to delays, financial losses, and damaged reputations. Businesses that fail to manage risks effectively may struggle with unexpected costs, compliance issues, and dissatisfied customers. The key to successful logistics risk management lies in proactive planning, real-time visibility, and strong contingency strategies.

Here’s how businesses can identify, assess, and mitigate risks to ensure smooth operations and prevent costly pitfalls.

-

Identifying Common Risks in Logistics

Logistics operations face a range of risks, including:

- Weather Disruptions: Storms, floods, and extreme weather can halt shipments and impact delivery schedules.

- Carrier Failures: A carrier’s financial instability or capacity issues can cause unexpected delays.

- Supply Chain Bottlenecks: Port congestion, customs clearance delays, or material shortages can slow down freight movement.

- Compliance Violations: Failing to meet safety regulations, customs laws, or environmental standards can result in hefty fines and shipment delays.

- Cybersecurity Threats: Data breaches and cyberattacks can compromise sensitive shipment information and disrupt supply chains.

By recognising these risks in advance, companies can prepare for potential disruptions and minimise their impact.

-

Strengthening Supply Chain Visibility

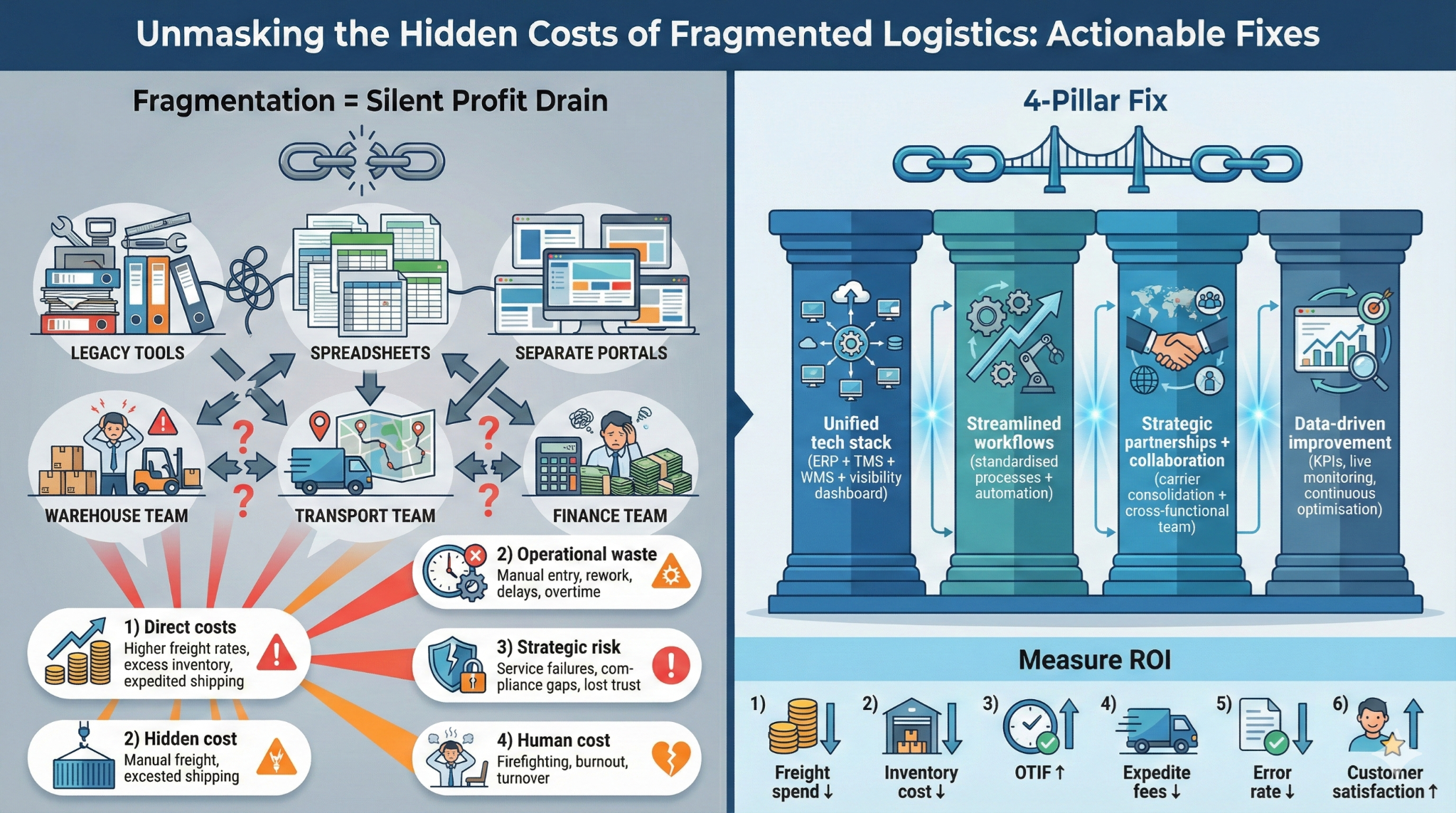

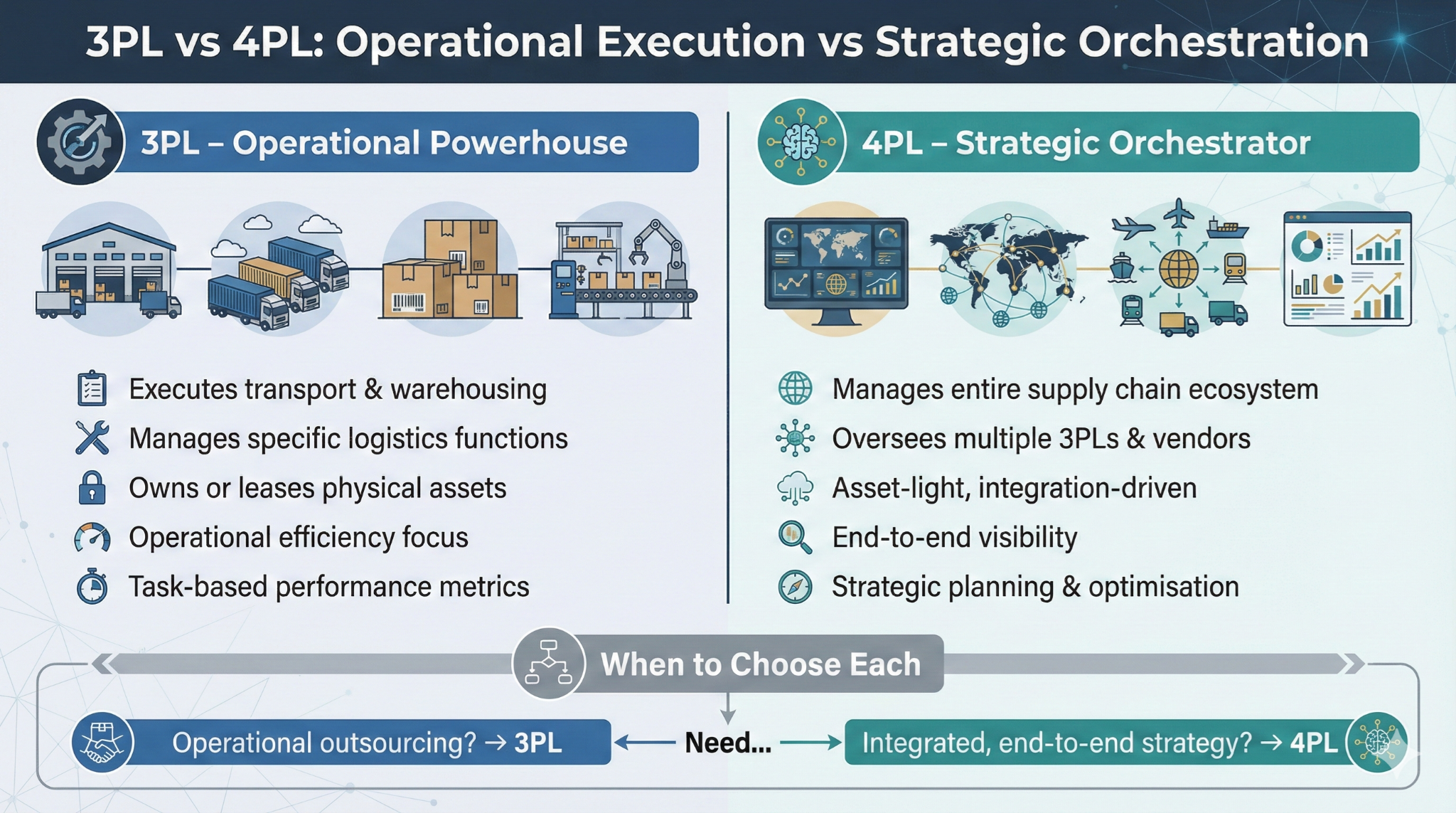

Real-time tracking and end-to-end visibility are crucial in mitigating risks. By leveraging GPS tracking, IoT sensors, and cloud-based logistics platforms, businesses can:

- Monitor shipments in real time

- Identify potential delays before they escalate

- Keep customers informed with accurate updates

- Optimise routes based on changing conditions

Early risk detection leads to faster problem resolution, helping businesses maintain reliability and avoid costly disruptions.

-

Developing Contingency Plans

A well-defined contingency plan ensures that logistics operations continue smoothly even when unexpected challenges arise. Businesses should:

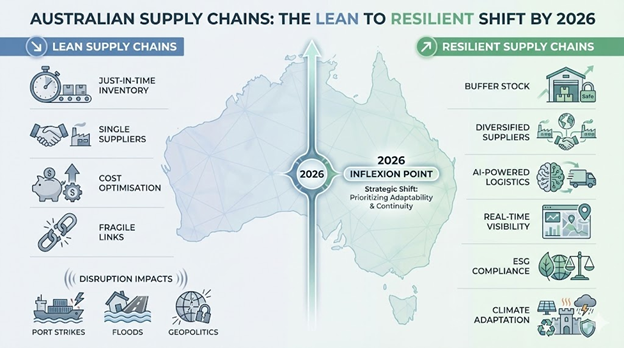

- Diversify carrier networks to avoid dependency on a single provider.

- Establish alternative routes for shipments in case of road closures or delays.

- Stock strategic inventory in multiple locations to reduce disruptions from supply chain bottlenecks.

- Train employees in risk response protocols to ensure quick and effective decision-making.

Planning for the unexpected helps logistics managers stay ahead of disruptions rather than react to them.

-

Implementing Data-Driven Risk Assessment

Predictive analytics and AI-powered tools help businesses identify potential risks before they become major issues. By analysing historical data and external factors, businesses can:

- Predict seasonal demand fluctuations

- Assess weather-related risks for specific routes

- Identify patterns in carrier performance to avoid unreliable partners

Data-driven decision-making enhances resilience and prevents unnecessary costs associated with poor planning.

-

Ensuring Compliance & Security

Regulatory compliance is a major factor in logistics risk management. Companies must stay up to date on local and international regulations, including:

- Customs procedures

- Environmental regulations

- Labour laws

Failure to comply can result in shipment seizures, fines, or legal actions. Investing in compliance tracking software and regular audits helps ensure adherence to industry regulations.

Conclusion

Logistics risks are inevitable, but their impact can be minimised through proactive planning, real-time monitoring, data-driven insights, and compliance measures. Companies that take a structured approach to risk management not only protect their operations but also build trust with customers and partners.