The end of the Australian financial year is crunch time. It’s when finance wants clean ledgers, sales wants stock to clear, and operations just want things to move on time. But in 2025, there’s a bigger cloud forming over EOFY planning — and it’s blowing in from offshore.

With Trump’s tariffs reigniting trade tensions and reshaping global freight flows, Australian businesses face a higher-than-usual risk of misjudging inventory, overcommitting on freight, or being caught flat-footed by supply disruptions.

Stock in a Storm: The Hidden Cost of Poor Planning

Every year we see the same pattern: businesses either overstock to chase tax deductions or understock out of caution, only to scramble in July when demand returns. But this year, the stakes are higher. If you import goods — even indirectly — the global tariff shifts could mean:

-

unexpected price hikes,

-

container delays,

-

carrier prioritisation shifting away from smaller-volume routes,

-

and storage cost blowouts due to backlog.

EOFY mistakes don’t just cost you once — they echo through Q1 of the new financial year.

How to Avoid a Freight Hangover After June 30

1. Know Your Inventory Posture — and Make It Intentional

Don’t let tax timing drive stocking decisions alone. Map out what’s in transit, what’s stuck at ports, and what’s at risk from tariff flow-ons. Aim to carry what you can move quickly, not what will sit idle and cost you in storage or spoilage.

2. Audit Your Warehouse and Freight Contracts

EOFY is the perfect moment to stress-test your capacity. Can your current warehouse handle a stock spike or roll-on effects from delayed containers? Are your freight rates locked, or variable to market pressure from tariff-driven congestion?

3. Prepare for Post-EOFY Volume Shocks

If tariffs tighten key global lanes, priority freight could get expensive. Work with your logistics partner now to lock in flexible, reliable options — especially for last-mile delivery where bottlenecks hurt your customer promise most.

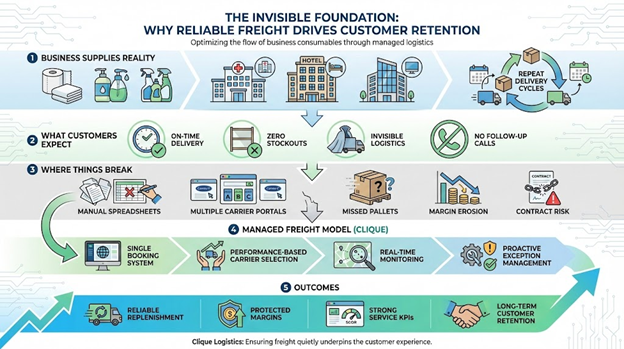

Logistics That Looks Forward, Not Just Back

At Clique Logistics, we treat EOFY as more than a stocktake. It’s a strategic reset — the moment to future-proof your freight operation. With market-aware planning, proactive alerts, and tailored solutions, we help businesses avoid the scramble and start the new financial year strong.

If you’re feeling unsure about your EOFY freight posture or inventory risk, now’s the time to talk. We’ll answer in 9 seconds, respond in 9 minutes, and make sure you never follow up on the same issue twice. That’s our 9:9 Never Customer Promise.