On paper, international freight forwarding looks straightforward. Goods move from a supplier to a port, onto a vessel or aircraft, through customs, and then into a domestic delivery network.

In reality, international freight forwarding is a series of handover points — and every handover is a potential failure point.

The process begins well before freight moves. Documentation accuracy, packaging standards, Incoterms and supplier readiness all determine how smoothly freight will flow. Many issues blamed on “shipping delays” actually originate at origin due to misalignment or missing information.

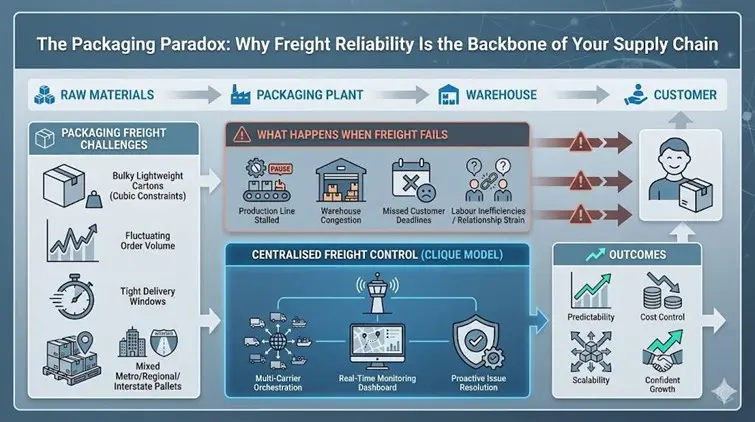

Once freight is in transit, control shifts between multiple parties: origin agents, shipping lines or airlines, port operators, customs brokers and domestic carriers. Without a clear coordinating party, issues can escalate quickly.

This is where international freight forwarding often breaks down. If no one owns the full journey, problems are addressed in isolation rather than resolved holistically. A delay at the port becomes a customs issue. A documentation error becomes a delivery failure.

Effective international freight forwarding in 2026 requires active coordination, not passive handover. A forwarder should be monitoring milestones, anticipating congestion risk and intervening early when something deviates from plan.

Customs clearance is another critical point. Clearance isn’t just about compliance — it’s about timing. Delays here can cascade into storage, delivery and customer commitment issues if not managed proactively.

Finally, the transition into the domestic network is where international freight often loses visibility. Best practice ensures international and domestic legs are aligned, with service levels and expectations clearly set.

International freight forwarding works best when one party owns the journey end-to-end — not just the booking.