Freight rarely fails in dramatic fashion. It drifts.

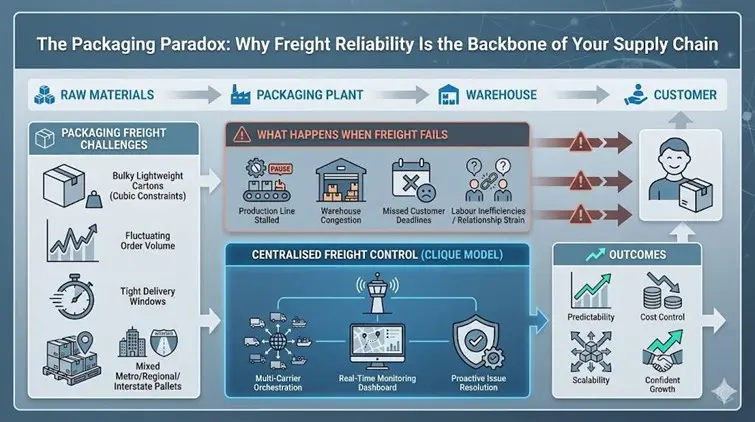

Processes that once worked slowly lose alignment. Volumes change. Customer expectations tighten. Carrier performance shifts. Over time, small inefficiencies compound into larger operational headaches.

Continuous improvement exists to stop that drift.

At Clique, continuous improvement in freight isn’t a once-a-year exercise. It’s embedded into how freight is reviewed, measured and adjusted over time. The focus isn’t on wholesale change, but on deliberate refinement.

Small improvements — better lane allocation, clearer service definitions, improved despatch accuracy — often deliver more value than major restructures. But only if someone is watching closely enough to spot them.

Data plays a role here, but only when paired with action. Performance metrics are used to identify trends, not to decorate dashboards. When something starts to move in the wrong direction, the response is early and targeted.

This approach protects service consistency and reduces operational noise. It also supports internal teams, who benefit from freight setups that evolve alongside the business rather than lag behind it.

Continuous improvement is particularly valuable through peak periods. Businesses that start planning early and refining freight structures ahead of pressure avoid the scramble that hits those who wait too long.

The goal isn’t perfection. It’s stability.