When you think about supply chain efficiency in Australia, you realise it’s not just about cutting costs but strategic optimisation. You’re likely aware that leveraging technology and building strong supplier relationships can significantly impact your operations. Have you considered how lean thinking and sustainability practices could further improve your efficiency? Investigating these strategies might uncover insights that could reshape your approach and drive better results. The question is, what specific actions can you take to implement these ideas effectively?

Importance of Supply Chain Efficiency

In today’s fast-paced market, understanding the importance of supply chain efficiency is vital for businesses aiming to thrive. An efficient supply chain can lead to significant cost reduction, which is fundamental for maintaining profitability. Even small improvements in freight productivity can create a ripple effect that boosts national welfare.

When you optimise logistics and distribution networks, you not only cut costs but also contribute to consumer affordability by keeping prices in check.

Recent disruptions, like natural disasters and labour shortages, have highlighted the need for resilient supply chains that can quickly adapt to changing conditions. This adaptability guarantees consistent service delivery, which is crucial for retaining customer trust and satisfaction.

Furthermore, a well-functioning supply chain supports the timely delivery of goods and services, aligning with the National Freight and Supply Chain Strategy’s goals for economic performance.

As you focus on improving supply chain efficiency, remember that it also aligns with sustainability objectives. Reducing waste and emissions through efficient practices meets environmental standards and appeals to today’s eco-conscious consumers.

Key Strategies for Optimisation

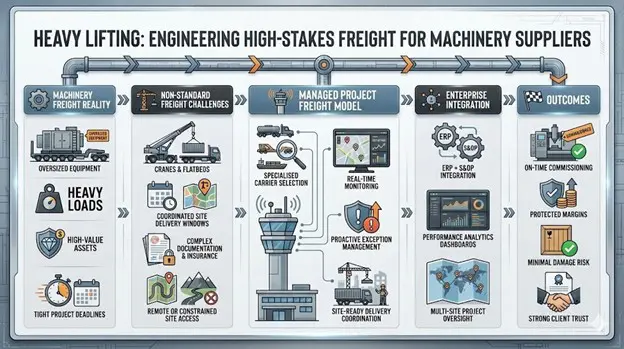

Optimising your supply chain begins with a strategic approach that targets key areas for improvement. One effective method is implementing lean thinking strategies. By focusing on waste reduction, you can improve efficiency and potentially reduce costs by up to 30%.

In addition, advanced technologies like AI and IoT can support real-time tracking and predictive analytics, improving demand forecasting accuracy by over 50%.

Building strong supplier relationships is another essential strategy. When you share information openly, you can reduce uncertainties and improve lead times by 20%. Furthermore, integrating blockchain technology promotes transparency and trust among supply chain partners, which is vital for effective risk management and compliance.

Be aware of the importance of scenario planning. By preparing for potential disruptions, you can maintain operational continuity and reduce costs associated with unplanned events by up to 40%.

Collectively, these strategies streamline your supply chain processes and strengthen your organisation’s resilience against risks. By adopting these key optimisation strategies, you’ll position your supply chain for sustained success and efficiency in a competitive environment.

Leveraging Technology in Logistics

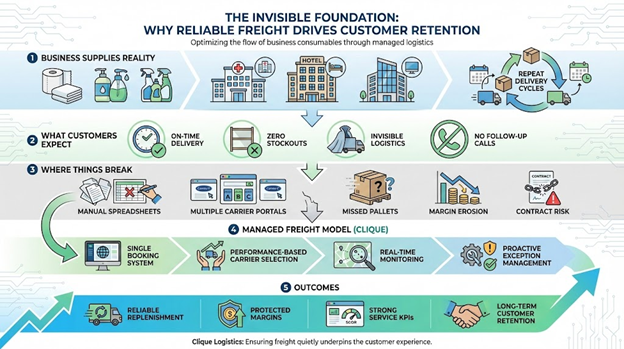

Technology is revolutionising logistics by enhancing efficiency and accuracy throughout the supply chain. With AI integration, you can improve demand forecasting, reducing stockouts and overstock situations. This leads to smarter inventory management and fewer losses.

IoT applications allow you to track goods in real-time, giving you better visibility across the supply chain. This means you can respond quickly to disruptions, minimizing delays.

Furthermore, the blockchain benefits you by providing a tamper-proof ledger that records every step of your product’s journey. This increases transparency and builds trust among all supply chain participants, ensuring consumers receive authentic products.

Robotics automation further streamlines your warehouse operations by performing repetitive tasks like data entry and order processing. This not only boosts efficiency but also allows your team to focus on strategic roles that drive growth.

Building Strong Supplier Relationships

Strong supplier relationships can transform your supply chain into a more agile and efficient operation. When you focus on building supplier trust, you facilitate open lines of communication that encourage timely information sharing and collaboration. This can lead to a remarkable 50% reduction in lead times, allowing you to respond faster to market demands.

Prioritising relationship management likewise aligns your production schedules and inventory levels with your suppliers’ capabilities, driving a 25% increase in inventory turnover rates.

Plus, organisations that maintain integrated supplier relationships face 70% fewer disruptions during crises, which improves your overall resilience and responsiveness.

A strong partnership with suppliers can yield significant cost savings—up to 20%—through joint process improvements and shared resources. These efficiencies not only streamline your operations but also strengthen your competitive edge.

Ultimately, by viewing supplier collaboration as vital to your success, you’re not just strengthening your supply chain; you’re also paving the way for a more sustainable future.

Sustainability in Supply Chain Practices

Sustainability in supply chain practices is no longer just a trend; it’s a necessity for businesses looking to thrive in today’s market. By focusing on renewable resources and integrating eco-friendly packaging, you can significantly reduce your environmental impact while improving your bottom line.

The National Land Transport Technology Action Plan promotes the use of low emissions vehicles, making freight more sustainable and aligning with Australia’s ambitious carbon reduction targets.

Adopting these sustainable practices helps you comply with regulations and improves your supply chain resilience. You’ll lessen risks associated with environmental disruptions and improve your operational efficiency.

Companies that adopt green technologies often see up to a 20% reduction in operational costs, boosting their profitability while improving their brand reputation and customer loyalty.

As the Australian government incentivises sustainable supply chain practices, now’s the time to invest in eco-friendly solutions. By prioritising sustainability, you’re not just doing your part for the environment; you’re also positioning your business for long-term success in a competitive market.

Accept sustainability, and watch your operational costs decrease while your reputation grows.

Enhancing Visibility and Collaboration

As you navigate the complexities of modern supply chains, improving visibility and collaboration becomes crucial for your success. Embracing data transparency allows you to reduce the Bullwhip Effect, leading to better demand forecasting and lower inventory costs.

Implementing information-sharing strategies creates a more agile supply chain. Collaborating with suppliers through integrated platforms improves real-time communication, enabling quick response to market changes and cutting lead times by up to 30%.

Furthermore, adopting IoT technology for asset tracking gives you 24/7 visibility into inventory levels, decreasing stockouts by 20% and boosting customer satisfaction.

Cloud-based solutions support effective collaboration across departments and increase operational efficiency by 25%. This seamless information flow aids faster decision-making, ultimately driving your supply chain’s performance.

In addition, implementing blockchain technology improves data transparency, allowing you to trace product journeys accurately. This builds trust among stakeholders and can lead to a 15% reduction in product quality and delivery disputes.

Continuous Improvement and Adaptability

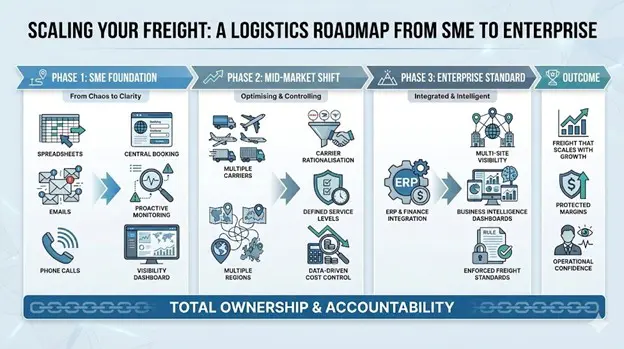

Improving visibility and collaboration lays the groundwork for continuous improvement and adaptability in your supply chain operations. To thrive, you need to assess your processes regularly. This helps you identify inefficiencies, ultimately reducing operational costs and boosting productivity.

Embracing lean thinking principles can eliminate waste and streamline operations, improving both efficiency and customer service.

Adopting agile methodologies is another vital strategy. This allows your organisation to quickly adapt to changing market demands, enabling you to respond effectively to disruptions while maintaining service levels.

Focus on performance metrics to measure your progress, guaranteeing that you’re on the right track toward improvement.

Fostering employee engagement is key in creating a culture of adaptability. Regular training and re-skilling of your workforce guarantee your team is equipped to utilise new technologies and processes effectively.

Moreover, advanced analytics and business intelligence tools can provide real-time insights into your supply chain performance, empowering you to make educated choices and implement proactive adjustments.

Conclusion

In today’s fast-paced market, prioritising supply chain efficiency is essential for your success. Implementing lean strategies, leveraging technology, and nurturing strong supplier relationships can significantly reduce costs and improve visibility. Embracing sustainability not only meets environmental goals but likewise appeals to conscious consumers. Remember, continuous improvement and adaptability are vital to staying competitive. By focusing on these strategies, you’ll drive operational efficiency and position your business for long-term growth and resilience.