Introduction: Navigating the Australian Logistics Labyrinth

For Australian small and medium-sized enterprises (SMEs), logistics is more than just moving boxes from A to B; it’s the critical backbone that dictates customer satisfaction, cash flow, and overall business performance. In a market where agility and efficiency are paramount, mastering the complexities of the supply chain can be the single most significant differentiator between stagnation and growth. As e-commerce continues its rapid expansion, with projections showing the sector could grow at a 23.9% CAGR through 2030, the pressure on small businesses to deliver quickly and reliably has never been greater.

The Critical Role of Logistics for Australian SME Success

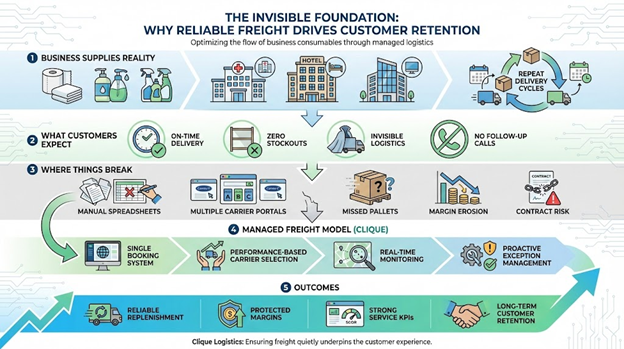

Effective supply chain management is no longer a luxury reserved for large corporations. For Australian SMEs, it’s a fundamental driver of success. A streamlined logistics operation directly impacts the bottom line by reducing costs, improving productivity, and freeing up capital. More importantly, it shapes the customer experience. In an era of high expectations, a seamless delivery process can build brand loyalty, while a single shipping error can lose a customer forever. Smart logistics enables small businesses to compete on a larger stage, access new markets, and build a reputation for reliability.

Why Australian SMEs Face Unique Logistics Challenges

Australian SMEs navigate a complex web of geographic scale, reliance on international trade, and resource constraints. They need more flexible and cost-effective solutions to reach every customer, regardless of these factors.

Australian SMEs operate within a unique and demanding environment. The sheer geographical scale of the continent creates inherent transportation complexities and costs. A dispersed population, coupled with reliance on international import and export routes, exposes businesses to significant supply chain disruptions. Unlike larger counterparts with dedicated logistics departments and vast resources, SMEs must navigate these challenges with limited budgets, smaller teams, and fewer assets, making strategic and efficient management essential.

What This Article Will Cover: The Top 7 Hurdles and Practical Solutions

This article cuts through the complexity to identify the seven most significant logistics hurdles facing Australian SMEs today. More than just highlighting problems, we will delve into the practical, intelligent strategies that successful businesses are using to overcome these obstacles. From managing soaring costs to embracing digital tools, you will gain actionable insights to transform your logistics from a challenge into a decisive competitive advantage.

Hurdle 1: Soaring Freight Costs & Inefficient Transportation Networks

Controlling operational expenses is a constant challenge for SMEs, and transportation costs are a significant front in that battle. The combination of fuel price volatility, carrier surcharges, and labour expenses can quickly erode profits, making efficient freight management a top priority.

The Reality of Australian Distances, Fuel Prices, and Infrastructure Limitations

Australia’s vast geography presents a formidable challenge. Shipping goods from Perth to Sydney is a significant logistical undertaking, not a simple domestic transfer. This distance magnifies the impact of fluctuating fuel prices and places a heavy burden on road and rail networks. For many SMEs, these inherent costs are unavoidable, especially as the road freight industry operates on razor-thin profit margins of around 3.9%, leaving little room for negotiation.

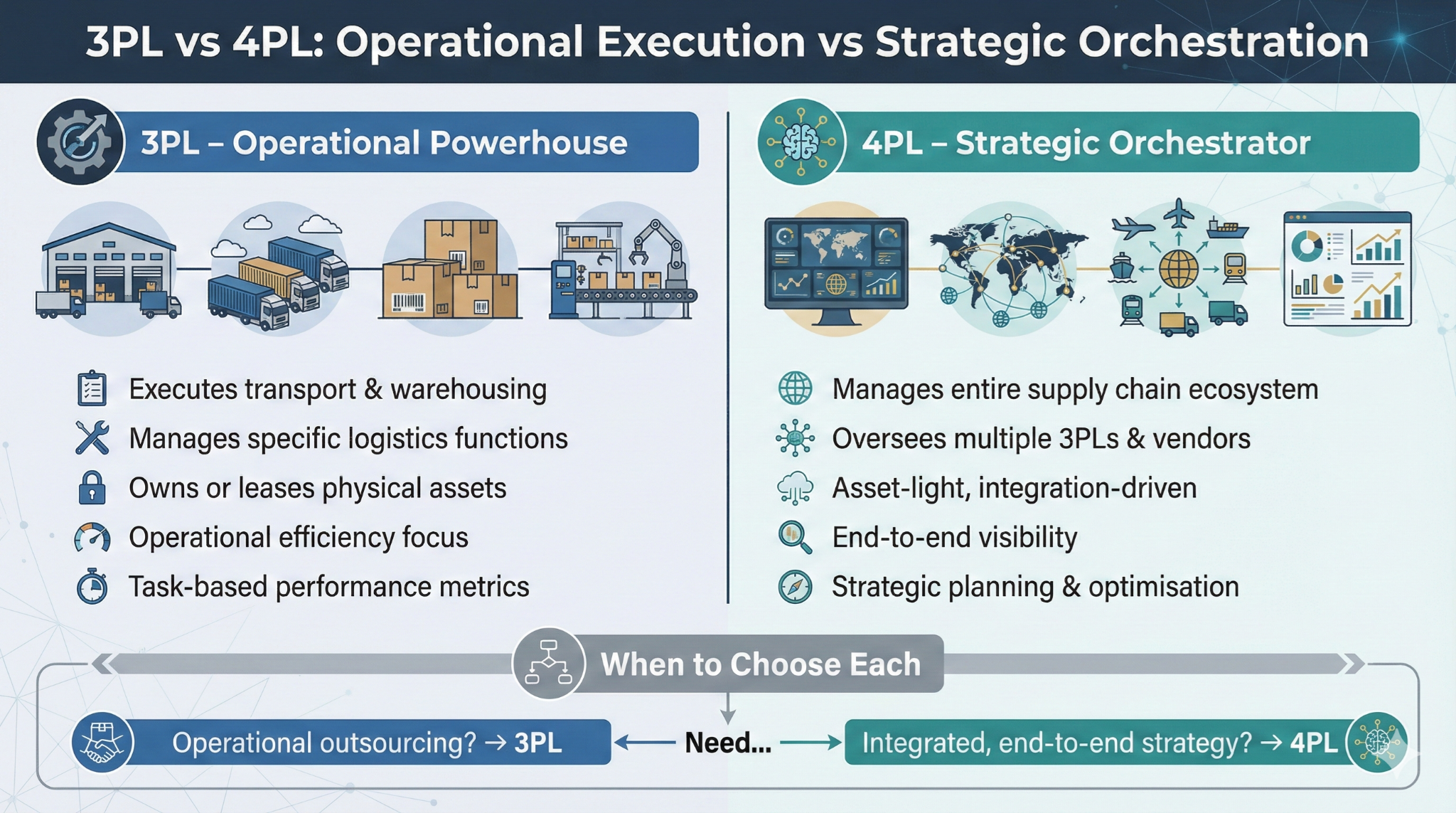

Smart Strategies for Optimising Transportation and Reducing Cost Burdens

Smart businesses combat these costs proactively. The first step is optimising packaging to reduce dimensional weight, a key factor in shipping costs. Consolidating smaller shipments into larger ones, either independently or through a third-party logistics (3PL) provider, can unlock significant volume discounts. Furthermore, leveraging technology such as route optimisation software helps identify the most efficient routes, reducing fuel consumption and delivery times. Exploring multi-modal transport options—using a combination of road, rail, and sea—can also provide cost-effective alternatives for less time-sensitive deliveries.

Hurdle 2: Complex Inventory Management & the Cash Flow Trap

Inventory is a delicate balancing act. Hold too little, and you risk frustrating customers with stockouts. Hold too much, and you tie up precious cash flow in assets that aren’t generating revenue. For SMEs, where capital is king, this balancing act is a high-stakes challenge.

The Double-Edged Sword: Costly Stockouts vs. Tying Up Capital in Overstock

Stockouts lead directly to lost sales and damage customer trust. In a competitive market, a customer who can’t buy from you today will likely buy from a competitor tomorrow. Conversely, overstocking drains cash flow that could be used for marketing, product development, or other growth initiatives. It also increases storage and insurance costs, further squeezing margins. This dilemma forces SMEs to walk a fine line between satisfying demand and maintaining financial health.

Smart Strategies for Precise Inventory Control and Optimisation

Technology is the key to escaping the inventory trap. Even basic inventory management software can provide the visibility needed to track stock levels, monitor sales trends, and forecast demand more accurately. Adopting principles like “Just-in-Time” (JIT) inventory, where materials arrive just as they are needed, minimises holding costs. For businesses scaling quickly, partnering with a 3PL provider for warehousing and fulfilment offers a flexible solution that converts fixed storage costs into a variable expense tied directly to sales volume.

Hurdle 3: Navigating Regulatory Compliance & Cross-Border Complexities

For SMEs looking to grow through import or export, the opportunities are immense, but so are the administrative hurdles. A complex web of local and international regulations can seem impenetrable, creating a significant barrier to entry for businesses without dedicated compliance teams.

The Maze of Australian and International Trade Regulations, Tariffs, and Biosecurity Rules

Every shipment that crosses a border is subject to a host of rules governing customs, tariffs, taxes, and documentation. Australian biosecurity laws are particularly stringent, adding another layer of complexity to the import process. Keeping up with these ever-changing regulations is a full-time job, and a single paperwork misstep can lead to costly delays, fines, or even the seizure of goods, jeopardising both profits and customer relationships.

Streamlining Compliance and Expanding Market Reach for Export and Import

Smart SMEs don’t try to become customs experts overnight; they partner with them. Freight forwarders and customs brokers are invaluable allies who navigate the regulatory maze on a business’s behalf, ensuring all documentation is correct and all duties are paid. Utilising digital platforms for trade documentation can also reduce errors and streamline the process. Proactively understanding Free Trade Agreements (FTAs) can unlock preferential tariff rates, providing a significant cost advantage and making Australian products more competitive on the world stage.

Hurdle 4: The Impact of Labour Shortages & Rising Workforce Costs

A successful logistics operation depends on skilled and motivated people, from warehouse pickers to delivery drivers. However, Australia’s tight labour market has created significant challenges for SMEs seeking to attract and retain the talent needed to keep their supply chains moving.

Australia’s Tight Labour Market: Skills Shortages, Wage Growth, and Employment Landscape Pressures

With nearly 97.2% of all Australian businesses being small, the competition for qualified logistics personnel is fierce. This has led to wage growth pressures and a shortage of specific skills, particularly in areas like data analysis and logistics technology management. For SMEs, competing with the salaries and benefits offered by larger corporations can be difficult, making workforce management a strategic priority.

Innovative Approaches to Workforce Management and Productivity in Logistics

To overcome these challenges, innovative businesses focus on boosting the productivity of their existing team. Investing in training and upskilling empowers employees and improves efficiency. Implementing performance metrics can help identify bottlenecks and reward high achievers. Technology also plays a crucial role: warehouse automation, such as barcode scanners and inventory systems, can reduce manual labour, minimise errors, and enable staff to focus on higher-value tasks, increasing overall operational productivity.

Hurdle 5: The Gap in Digital Transformation & Technology Adoption

In today’s logistics landscape, data is as important as the physical goods being moved. Yet many SMEs are hesitant to adopt digital tools, leaving them at a competitive disadvantage to more tech-savvy rivals.

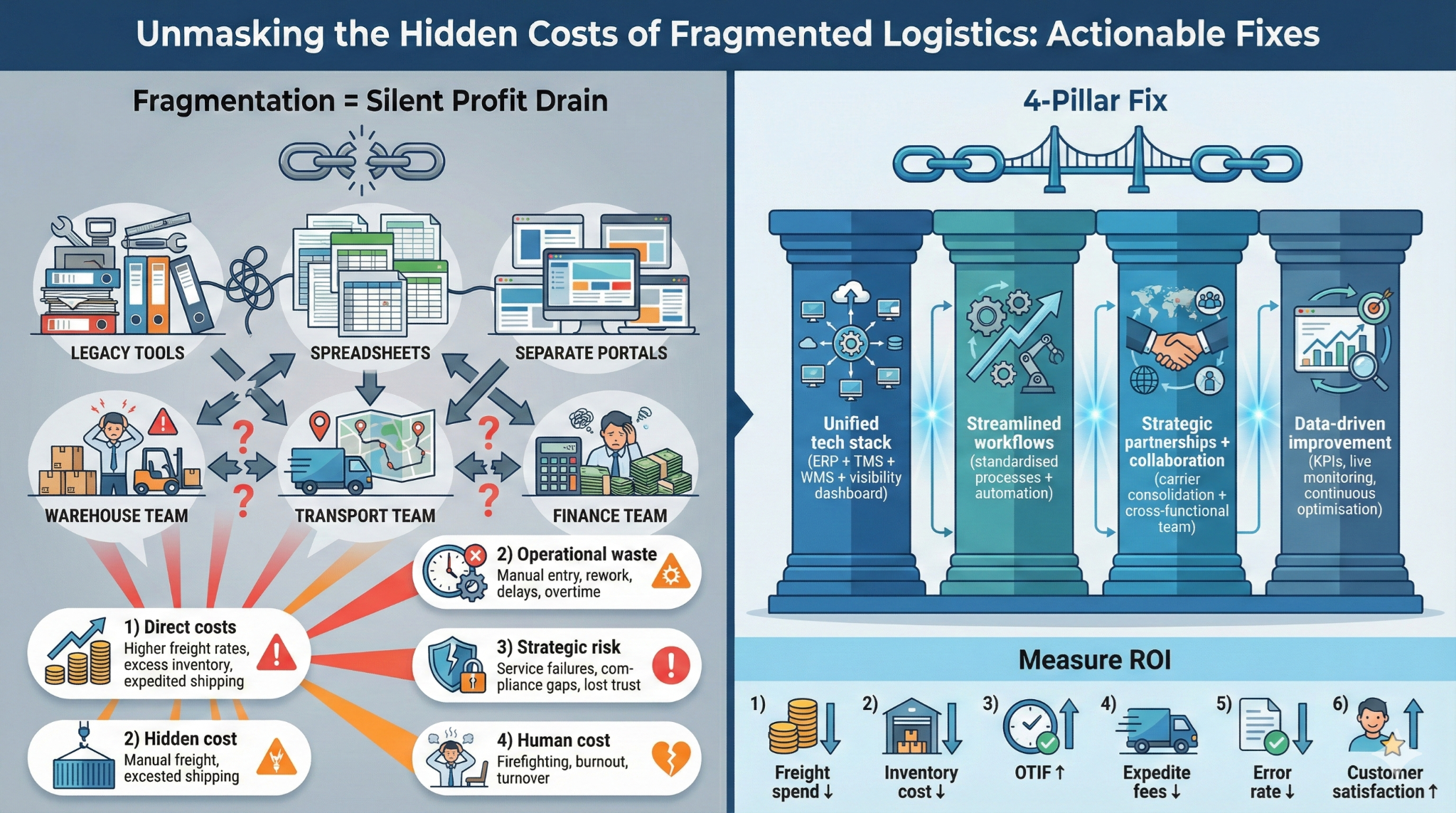

Overcoming Resistance to Change and Legacy System Dependencies in SMEs

The barriers to technology adoption are often cultural and financial. Fear of the unknown, perceived costs of new systems, and reliance on outdated “pen and paper” processes can create significant inertia. Many small businesses operate on legacy systems that don’t integrate well with modern logistics platforms, creating data silos and preventing a holistic view of the supply chain.

Embracing Digital Tools for a Competitive Logistics Advantage

The key to successful digital transformation is a phased and strategic approach. SMEs don’t need a complete overhaul overnight. Starting with affordable, cloud-based solutions for core functions like shipping, tracking, and inventory management can deliver immediate returns. The growth of e-commerce in Australia, which rose 12.5% in Q1 2025, underscores the need for these tools. This digital foundation provides real-time visibility, improves decision-making, enhances performance, and ultimately enables SMEs to meet modern customers’ demand for speed and transparency.

Hurdle 6: Mitigating Supply Chain Disruptions & Risks

Recent global events have shown just how fragile supply chains can be. From geopolitical tensions to natural disasters, disruptions can halt the flow of goods, creating uncertainty for businesses and their customers.

Navigating Global Volatility and Local Impacts on Australian Supply Chains (Supply Chain Disruptions, Demand Risks, Operational Risks)

As an island nation heavily reliant on international trade, Australia is particularly vulnerable to global supply chain disruptions. However, risks can also be local, from port strikes to extreme weather events. These events create uncertainty in supply, demand, and operations. While a National Australia Bank survey suggests pressures are easing, the potential for disruption remains a constant threat that requires proactive management.

Building Resilient and Agile Supply Chains for Business Continuity

The goal is not to avoid all risk—which is impossible—but to build a supply chain that can bend without breaking. Diversifying suppliers, both locally and internationally, reduces dependence on a single source. Holding a strategic buffer stock of critical components can provide a cushion against short-term delays. Most importantly, building strong, transparent relationships with key suppliers and logistics partners fosters the collaboration needed to navigate crises effectively and ensure business continuity.

Hurdle 7: Overcoming Infrastructure Limitations & Geographical Challenges

Australia’s vast and varied landscape is a core part of its identity, but it also creates significant logistical hurdles. Moving goods efficiently across the country requires careful planning and a deep understanding of its unique infrastructure.

Australia’s Unique Landscape: Vast Distances, Varied Infrastructure, and Remote Access Challenges

The challenge isn’t just distance but also infrastructure variability. Major cities are well connected, but reaching regional and remote customers can be slow and costly. This “last-mile” delivery is often the most complex and expensive part of the journey. Furthermore, rising warehousing rental costs, which increased by an average of 9% in 2023, put additional pressure on SMEs needing storage in prime urban locations.

Strategic Planning for Distribution, Storage, and Last-Mile Delivery

Innovative SMEs address this by strategically managing their distribution networks. Instead of a single, central warehouse, some businesses benefit from smaller, decentralised storage hubs closer to key customer populations. Partnering with 3PLs who have established national networks provides immediate access to this infrastructure without the upfront investment. For last-mile delivery, collaborating with multiple carriers or specialised local couriers can provide more flexible and cost-effective solutions to reach every customer, regardless of location.

Holistic Strategies for a Resilient Australian SME Logistics Future

Overcoming individual hurdles is essential, but building a truly resilient and competitive logistics operation requires a holistic, forward-thinking approach. The smartest Australian SMEs understand that logistics is not a cost centre to be minimised, but a strategic function that drives growth, customer loyalty, and long-term value.

Embracing a Digital-First Mindset for End-to-End Logistics Transformation

A digital-first mindset is the foundation of modern logistics. It means moving beyond isolated spreadsheets and embracing integrated systems that provide a single source of truth across the entire supply chain. This end-to-end visibility allows for proactive decision-making, faster response times to disruptions, and continuous improvement in performance and productivity.

Building Stronger Partnerships and Collaboration Across the Supply Chain

No SME can master logistics alone. Success lies in building a strong ecosystem of partners, including reliable suppliers, tech-savvy 3PL providers, and expert freight forwarders. True collaboration, based on shared data and mutual trust, transforms the supply chain from a simple series of transactions into a powerful, integrated network working towards a common goal: delivering value to the end customer.

Prioritising Sustainability Practices for Long-Term Value and Brand Reputation

Finally, sustainability is no longer a niche concern; it is a core component of a modern logistics strategy. Efficient route planning, optimised packaging, and reduced waste not only lower a business’s environmental footprint but also reduce costs. As consumers increasingly favour brands with strong ethical practices, demonstrating a commitment to sustainability can enhance brand reputation, attract new customers, and build lasting value for the business.