Introduction: Navigating Australia’s Busiest Supply Chain Gauntlet

For Australian businesses, the period from the pre-Christmas build-up to the post-Chinese New Year normalisation is the most critical and challenging time of the year. It’s a supply chain gauntlet that tests inventory management, financial resilience, and operational agility. With online spending hitting a record-breaking AU$69 billion and global disruptions adding unprecedented volatility, navigating this period requires more than just planning—it demands a strategic survival guide.

The Unique “Dual Rush” Challenge for Australian Businesses

Unlike many global counterparts, Australian businesses face a unique “dual rush.” First comes the intense consumer demand of the Christmas season, straining inventory and logistics. This is immediately followed by the need to prepare for the Chinese New Year. During this period, a significant portion of the global supply chain, particularly for manufactured goods, grinds to a halt. This creates a challenging cycle of managing a sales peak followed swiftly by a significant supply disruption.

Understanding the Current Climate: Global Disruptions and Rising Costs

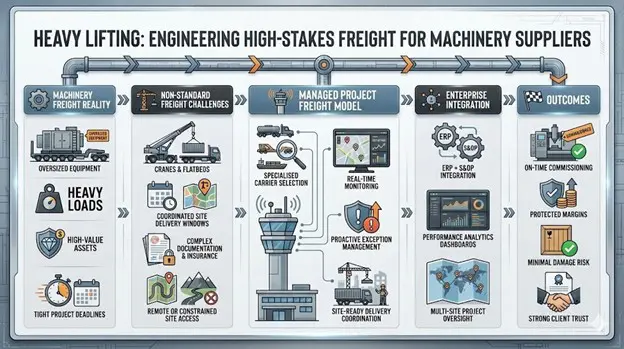

This year, the challenge is amplified. Geopolitical events are causing significant ripples across the supply chain. The situation in the Red Sea has rerouted shipping lanes, delaying shipments and increasing operational complexity. Furthermore, the persistent threat of US tariff increases creates uncertainty for exporters and importers alike, potentially leading to front-loading orders and further straining logistics. The direct consequence across industries is rising freight costs, putting immense pressure on margins when businesses can least afford it.

Phase 1: Tackling the Christmas Rush – Immediate Challenges and Strategies

The festive season is a period of immense opportunity and significant operational stress. Success hinges on anticipating and managing the inevitable logistical crunch.

The Anatomy of the Christmas Freight Crisis

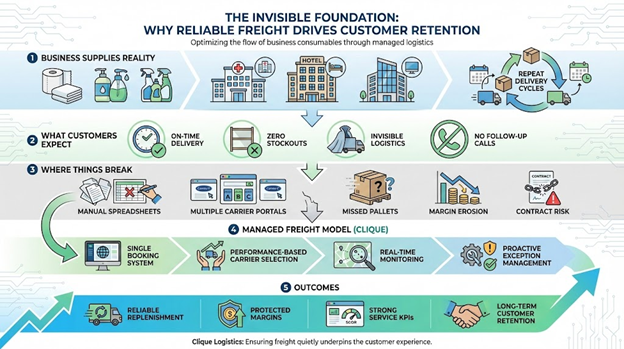

As demand surges, so does the pressure on every link in the supply chain. Ports become congested, domestic couriers face backlogs, and per-shipment costs rise. This peak-season strain means that a minor delay at one point can have cascading effects, resulting in missed delivery windows and dissatisfied customers. With retail sales showing strong growth, the volume moving through these networks is higher than ever, which is magnifying potential bottlenecks.

Proactive Inventory and Demand Management

The key to surviving the Christmas rush is to plan. With consumer behaviour shifting, nearly one in three Australian shoppers (29%) are buying Christmas gifts earlier, prompting businesses to adjust their timelines. This involves forecasting demand more accurately, placing supplier orders well in advance, and maintaining a safety stock buffer for best-selling items to avoid stockouts during the peak trading window.

Securing Your Shipments: Logistics and Carrier Diversification

Relying on a single logistics partner during this period is a high-risk strategy. Diversifying your career relationships can provide flexibility if one provider becomes overwhelmed. It’s also crucial to maintain clear communication with freight forwarders to get real-time updates on your shipments and proactively manage customer expectations regarding potential delays.

Financial Resilience for the Christmas Peak

Managing the surge in both revenue and expenses is critical. Increased transaction volumes, higher staff costs, and unexpected freight surcharges can strain business finances. This is where having a robust financial system is non-negotiable. Efficiently processing payments, including cash sales, and having a clear, real-time view of your financial position allows you to make agile decisions when pressures are highest.

Phase 2: The Critical Transition – From Festive Frenzy to Lunar Lull Preparation

The period immediately following Christmas is not a time to rest; it is a crucial window for analysis and preparation for the next major supply chain event: the Chinese New Year.

Post-Christmas Inventory Reconciliation and Sales Analysis

Once the festive rush subsides, the first step is a thorough stocktake and sales analysis. Understanding what sold well, what didn’t, and your exact inventory levels is essential. This data provides the foundation for accurate forecasting and informs the orders you need to place before factories in China close for the holiday period.

Early Financial Review and Forecasting for the Upcoming Period

Reviewing your financial performance during the Christmas peak provides critical insights. Analyse profit margins, transaction costs, and overall cash flow. Use this data to forecast your financial needs for the coming months, accounting for the large upfront payments required for pre-Chinese New Year orders and the subsequent period of reduced sales and no new stock arrivals.

Bridging the Gap: Maintaining Supplier Relationships and Communication

This is the time to strengthen communication with your suppliers. Confirm their holiday schedules, final order deadlines, and production timelines. A strong relationship can be the difference between getting your shipment out before the shutdown or having it delayed by several weeks. Clear, proactive communication ensures both parties are aligned on expectations.

Phase 3: Mastering Chinese New Year – Proactive Planning and Mitigation

The Chinese New Year shutdown is a predictable but highly disruptive event. Mastering it requires strategic foresight and meticulous planning.

Understanding the Impact of the Chinese New Year on Global Supply Chains

During Chinese New Year, many Chinese factories can experience complete shutdowns for up to six weeks. This halt in production affects everything from manufacturing to port operations. The lead-up to the holiday creates a frantic rush to dispatch goods, causing port congestion and a spike in freight costs, with shipping rates expected to surge by 20-30%.

Communication is Key: Engaging with Chinese Exporters and Suppliers

Confirm final production and shipping deadlines with your suppliers months in advance. Understand their capacity limits in the frantic pre-holiday period and book your shipping space early. Miscommunication during this phase can result in your goods being left at the dock until after the holiday.

Strategic Ordering and Lead Time Management

To mitigate the impact of the shutdown, businesses must “buy forward.” This means ordering enough inventory to cover not only the holiday period itself but also the subsequent weeks it takes for production and shipping to return to normal. This requires a significant capital outlay and careful management of warehouse space.

Exploring Alternative Sourcing and Shipping Routes

While China remains a dominant manufacturing hub, this period highlights the risk of over-reliance on a single region. Prudent businesses use this time to explore alternative sourcing options in other countries. Similarly, investigating alternative shipping routes or transport modes, while potentially more expensive, can serve as a valuable contingency.

Leveraging Technology for End-to-End Supply Chain Resilience

Navigating this dual rush requires more than manual processes. Integrated technology provides the visibility and control needed to manage finances and operations effectively.

Integrated Financial and Operational Systems

A disconnected system where sales data, inventory, and financial records are siloed is a recipe for disaster during peak season. Integrating your Point of Sale (POS) system—whether a custom solution or an industry standard like Oracle Simphony—with your financial platform is crucial for a single source of truth.

Zeller: Your Financial Co-Pilot for the Dual Rush

Zeller provides a unified ecosystem to manage the financial complexities of this period. The Zeller Dashboard provides a real-time view of all sales and settlements, enabling you to track performance and manage cash flow from anywhere via the Zeller App. The Zeller Transaction Account streamlines cash flow, while Zeller Invoices helps you get paid faster by suppliers or B2B clients. For businesses needing bespoke solutions, Zeller’s developer suite, with its SDKs and APIs, enables seamless integration with existing software.

Digital Tools for Inventory Tracking and Logistics Management

Beyond payments, leveraging digital tools for inventory management and shipment tracking is essential. These platforms provide real-time data, enabling you to anticipate stock shortages and track your goods from the factory to your warehouse, giving you the visibility needed to manage customer expectations accurately. For customer-facing businesses, features like Pay at Table, powered by solutions such as Linkly, can streamline service during busy periods.

Mitigating Broader Supply Chain Risks for Australian Businesses

The period from Christmas to Chinese New Year is a microcosm of the broader risks in the modern supply chain. Building long-term resilience is the ultimate goal.

Addressing Geopolitical Disruptions: The Red Sea and Beyond

Events like the disruptions in the Red Sea are becoming more common. These incidents highlight the fragility of global trade routes and the sudden impact they can have on freight costs. Businesses must stay informed and build contingency plans that account for these unpredictable events.

Building Supply Chain Agility and Contingency Plans

Agility is about having options. This means developing a playbook for various disruption scenarios. What is your backup plan if a key supplier is unavailable? What alternative shipping routes can you activate? Having these plans in place before a crisis hits is essential.

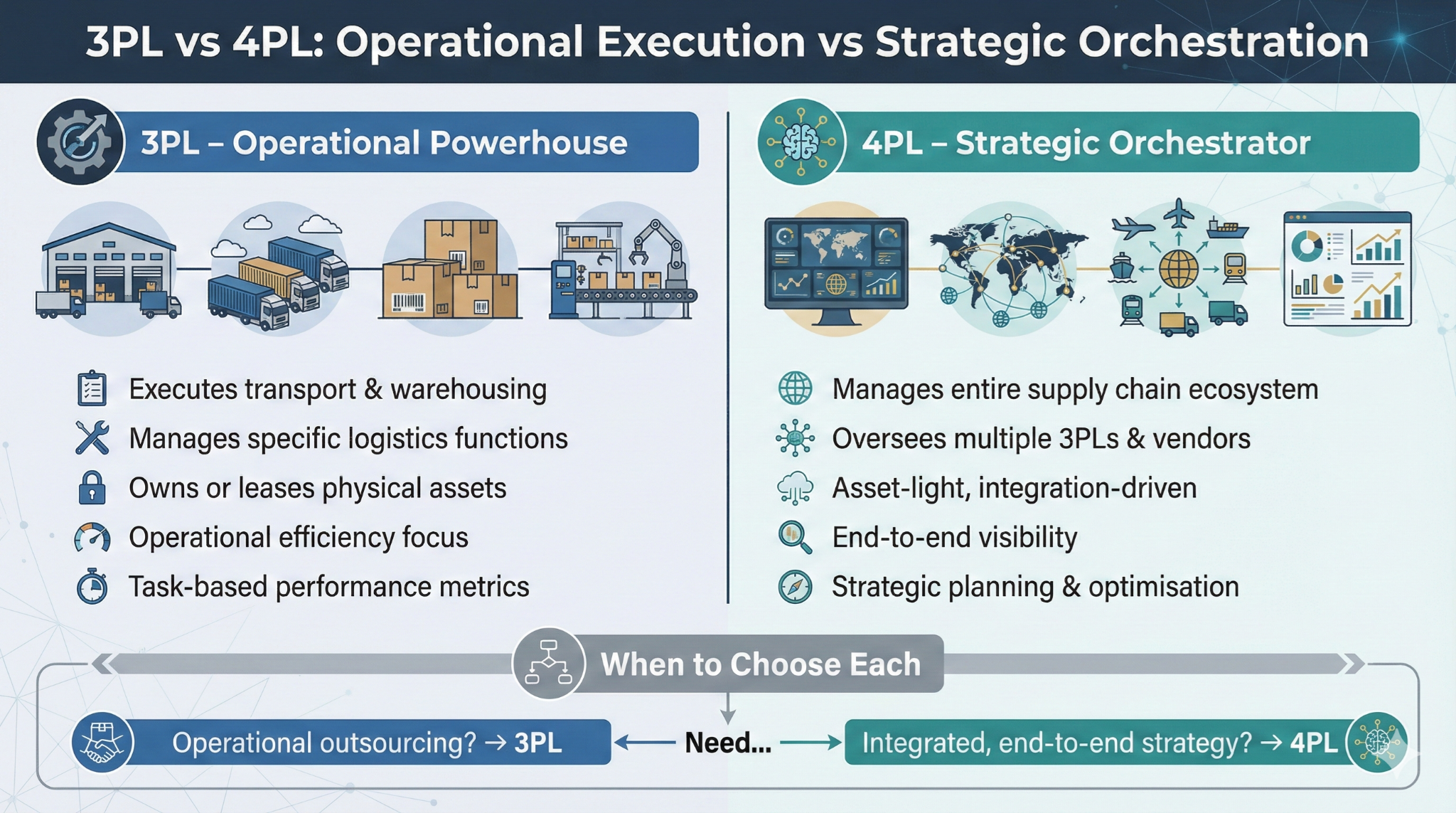

Diversification Strategies: Suppliers, Markets, and Logistics

The ultimate strategy for long-term resilience is diversification. This involves diversifying your supplier base across different geographic regions, exploring new markets for your products, and establishing relationships with multiple logistics providers. This spreads your risk and reduces your vulnerability to any single point of failure.

Conclusion: Thriving Through the Peaks – A Roadmap for Australian Businesses

The annual gauntlet from the Christmas rush to the Chinese New Year is a defining challenge for Australian businesses. Success is not merely about surviving; it’s about turning these pressures into an opportunity to build a more resilient, agile, and profitable operation.

The Imperative of Proactive Planning and Financial Agility

The core lesson is the power of proactivity. Waiting for disruptions to occur is a losing strategy. Strategic planning, from early ordering to financial forecasting, is paramount. Financial agility—the ability to manage cash flow effectively and make swift, data-driven decisions—is what separates businesses that thrive from those that struggle.

Empowering Your Business with the Right Tools and Partnerships

You don’t have to navigate this alone. The right technology partner acts as a force multiplier. An integrated financial platform like Zeller provides the tools—from the Zeller Transaction Account and Personalised Zeller Debit and Corporate Cards for expense management to the Zeller Dashboard for crucial oversight—to give you control over your business finances when you need it most.

Beyond Survival: Building Long-Term Resilience and Growth

By mastering this annual cycle, you are not just solving a short-term problem. You are building the foundations of a robust, future-proof business. The strategies of diversification, technological integration, and proactive financial management are the cornerstones of long-term resilience and sustainable growth in an increasingly uncertain global market.