As 2026 approaches, businesses face a pivotal moment where sustainability is no longer a peripheral concern but a core strategic imperative. The growing urgency of climate change, coupled with increasing consumer and regulatory pressure, demands decisive action. Reducing your company’s carbon footprint—the total amount of greenhouse gases generated by your activities—is not just an environmental obligation; it’s a critical component of modern business resilience. This article provides a straightforward roadmap for businesses to slash their emissions and build a more sustainable future significantly.

Introduction: Why Businesses Must Prioritise Carbon Reduction in 2026

The Urgency of Climate Action and Shifting Business Landscape

The conversation around climate change has evolved from distant warnings to immediate economic realities. Stakeholders, from investors to customers, now scrutinise a company’s environmental impact, influencing purchasing decisions and capital allocation. In 2026, a proactive approach to reducing greenhouse gas emissions is essential to navigate this new landscape and mitigate the risks associated with a changing climate.

Beyond Compliance: The Business Case for Sustainability

Embracing sustainability offers compelling competitive advantages. Slashing energy consumption directly lowers operational costs. A strong commitment to environmental responsibility enhances brand reputation, attracting eco-conscious consumers and top talent who seek value-aligned employers. Proactive carbon reduction is a strategic investment in long-term profitability and market leadership.

A Practical Roadmap for Impactful Change

This guide breaks down the process into clear, manageable steps. By focusing on high-impact areas like energy, transport, and waste, any business can make meaningful progress toward reducing its environmental impact without overwhelming its resources.

Step 1: Baseline Your Impact with a Carbon Footprint Assessment

Understanding Your Current Carbon Footprint

Before you can manage your emissions, you must measure them. A carbon footprint assessment identifies all sources of greenhouse gases your business is responsible for. These are categorised into three scopes:

- Scope 1: Direct emissions from owned or controlled sources (e.g., fuel burned in company vehicles).

- Scope 2: Indirect emissions from purchased electricity, steam, heating, and cooling.

- Scope 3: All other indirect emissions in your value chain (e.g., supply chain activities, business travel, waste disposal).

Tools and Methods for Measurement

Numerous tools can help quantify your carbon dioxide output. Frameworks like the ISO 14064 standards provide a structured approach to quantifying and reporting greenhouse gas emissions. For a deeper analysis, a life-cycle assessment (LCA) can evaluate a product’s environmental impact from raw material extraction through disposal.

Setting Clear, Achievable Emission Reduction Targets

Once you have a baseline, you can set meaningful goals. Science-based targets align your reduction efforts with the latest climate science, ensuring you meet the objectives of the Paris Agreement. Aiming for Net Zero emissions is an ambitious long-term goal that signals a deep commitment to sustainability.

Step 2: Revolutionise Energy Efficiency Across Operations

Conducting a Comprehensive Energy Audit

An energy audit is the first step toward efficiency. It provides a detailed breakdown of your energy consumption, pinpointing where energy is being wasted. This data forms the foundation of your energy-saving strategy, highlighting the most impactful areas for improvement.

Optimising Building Infrastructure and Systems

Simple upgrades yield significant results. Switching to energy-efficient LEDs can cut lighting energy use by up to 80%. Optimising HVAC systems through regular maintenance and smart thermostats prevents unnecessary energy consumption. Investing in modern, energy-efficient equipment further reduces your dependence on fossil fuels.

Smart Energy Management Systems

Technology can automate energy savings. Innovative systems monitor energy consumption in real-time, using AI to optimise usage across your facilities. These platforms identify anomalies and provide actionable insights, allowing for continuous improvement in energy efficiency.

Reducing Industrial Energy Use

In manufacturing, industrial processes are a significant source of energy use. Upgrading to a variable-speed drive air compressor, for example, matches energy output to real-time demand, drastically cutting electricity consumption compared to fixed-speed models.

Step 3: Transition to Renewable Energy Sources

On-Site Renewable Energy Generation

Generating your own clean power is a powerful way to reduce emissions. Installing solar panels on rooftops or available land provides a direct source of renewable energy, lowering electricity bills and reducing your carbon footprint. Photovoltaic systems are increasingly cost-effective for office buildings and industrial facilities.

Purchasing Green Energy

If on-site generation isn’t feasible, you can switch to a utility provider that offers energy from renewable energy sources like wind or solar. Alternatively, purchasing Renewable Energy Credits (RECs) supports the generation of clean energy elsewhere on the grid, effectively offsetting your consumption.

Exploring Community Solar and Off-Site Renewable Energy Options

Community solar programs allow multiple customers to benefit from a single, shared solar array. This is an excellent option for businesses that lack suitable roof space. Power Purchase Agreements (PPAs) for off-site renewable projects offer another path to securing long-term, clean energy.

Step 4: Green Your Business Travel, Transportation, and Logistics

Reducing Business Travel and Promoting Remote Work

The easiest way to cut transport emissions is to reduce travel. Encourage virtual meetings whenever possible and adopt flexible remote work policies. This not only lowers your carbon footprint but can also improve employee work-life balance and reduce overhead costs.

Sustainable Fleet Management

For companies with vehicle fleets, transitioning to electric vehicles (EVs) eliminates tailpipe emissions. If a complete transition isn’t possible, focus on optimising delivery routes to minimise fuel consumption and implementing regular vehicle maintenance schedules to ensure peak efficiency.

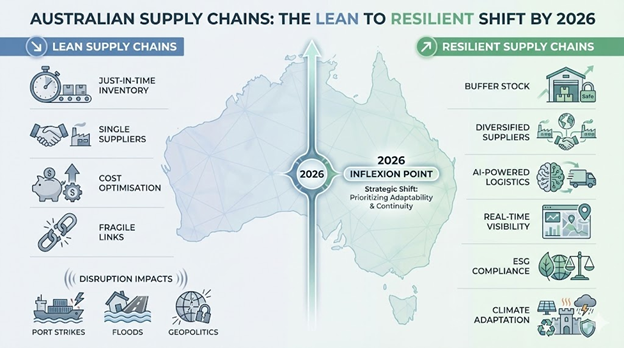

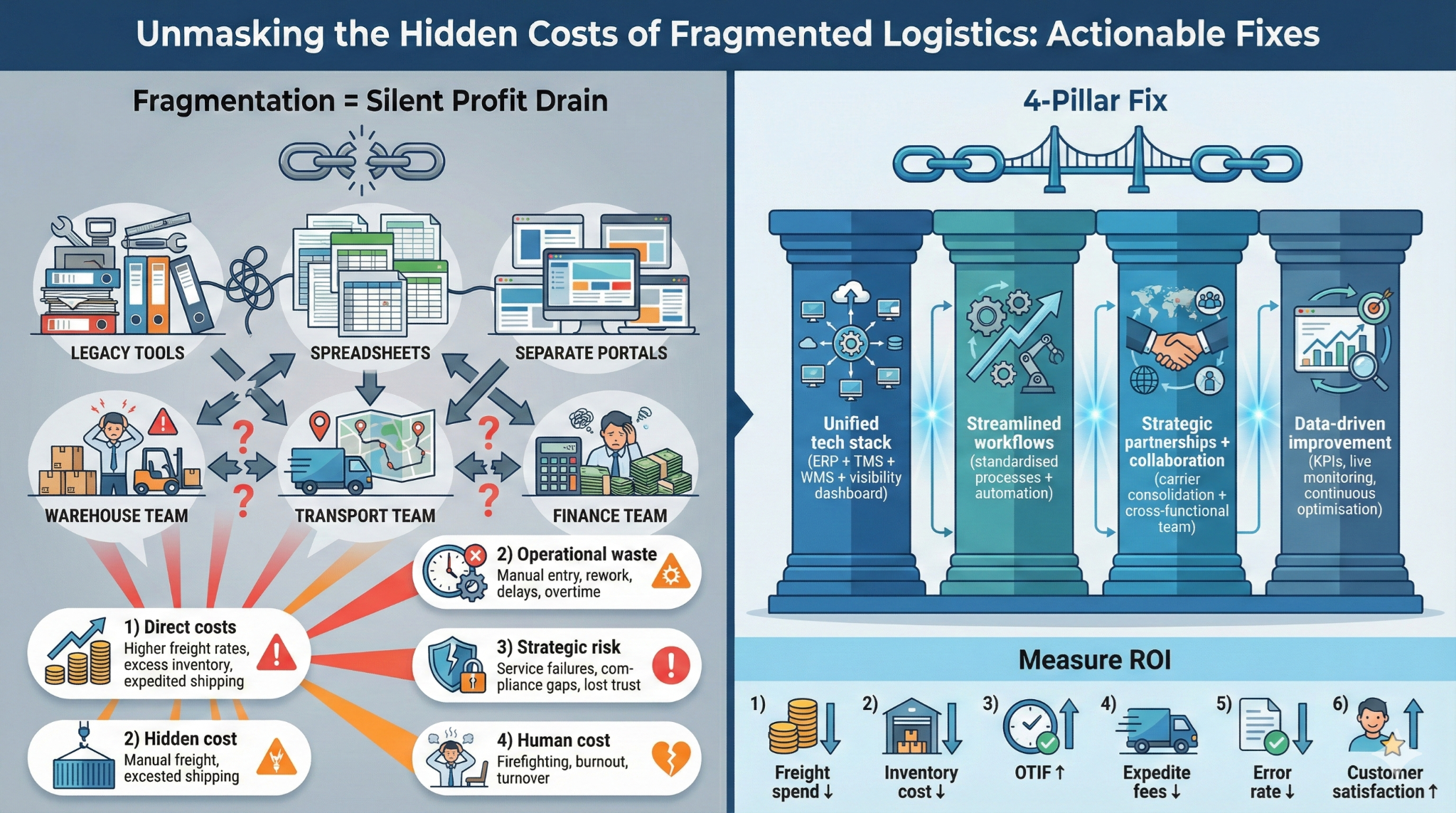

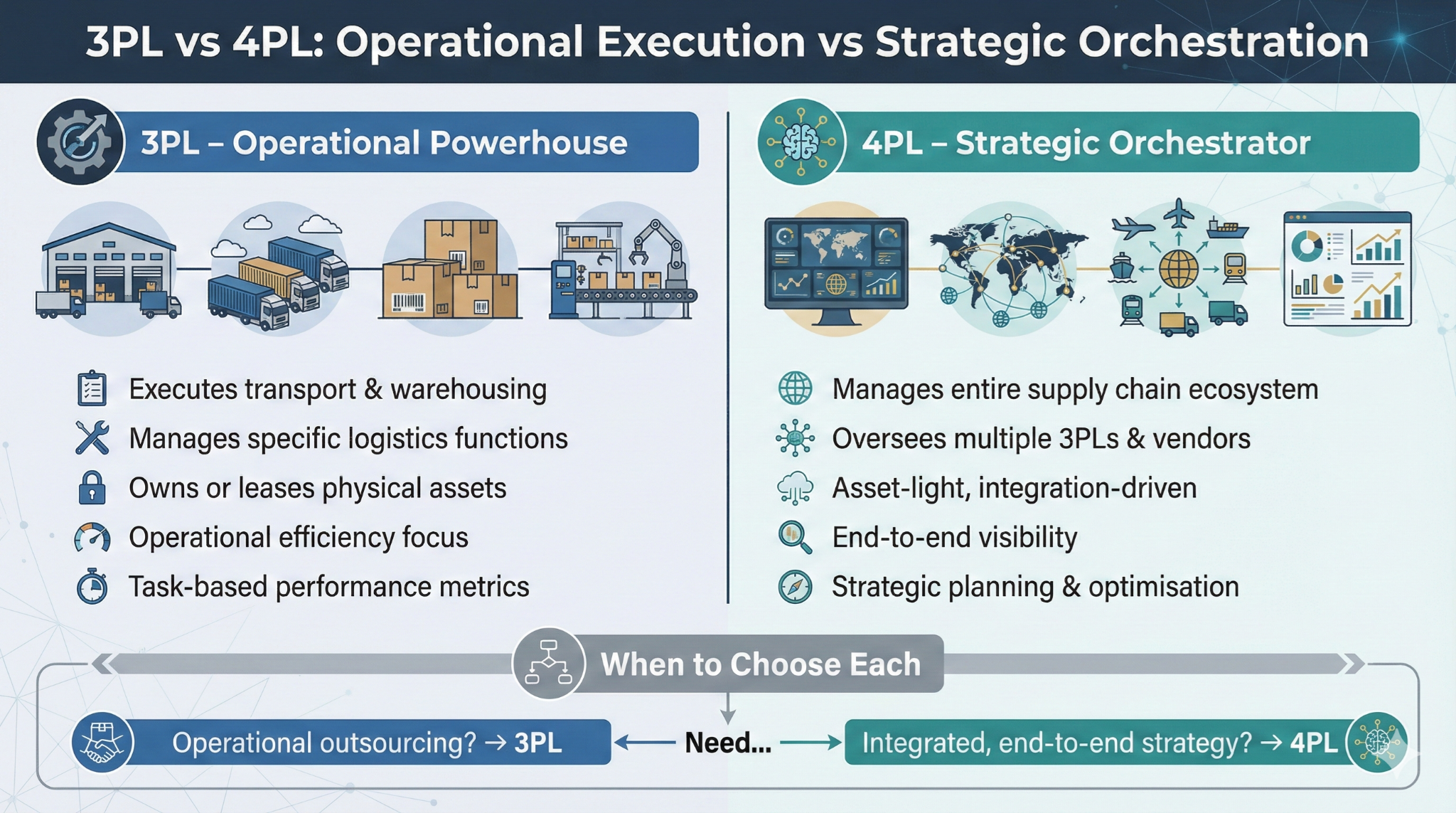

Collaborating with Eco-Conscious Logistics Partners

Your supply chain extends your environmental impact. Partner with third-party logistics (3PL) providers that prioritise sustainability through efficient transport methods, route optimisation, and investment in low-emission fleets.

Step 5: Master Waste Reduction and Embrace the Circular Economy

Implementing Robust Waste Management Practices

Effective waste management starts with the “three Rs”: Reduce, Reuse, and Recycle. Implement a comprehensive recycling program for paper, plastics, glass, and metals. Clearly label bins and educate employees to minimise contamination and maximise diversion from landfills.

Minimising Food Waste

If your facility has a cafeteria, addressing food waste is crucial. Implement composting for food scraps to prevent the release of methane, a potent greenhouse gas. Sustainable procurement practices and smaller portion options can further reduce waste.

Rethinking Product Life Cycles and Packaging

Embrace circular-economy principles by designing products for durability, repairability, and eventual disassembly. Minimise packaging and opt for recycled, recyclable, or biodegradable materials to reduce your products’ carbon footprint from start to finish.

Responsible Electronic Waste Management

Electronics contain valuable materials and hazardous substances. Partner with a certified e-waste recycling or IT Asset Disposition (ITAD) vendor to ensure that old computers, phones, and other devices are disposed of responsibly, keeping toxic materials out of landfills.

Step 6: Cultivate a Sustainable Supply Chain and Procurement

Vetting and Partnering with Sustainable Suppliers

Your suppliers heavily influence your Scope 3 emissions. Develop a supplier code of conduct that includes environmental criteria. Request sustainability reports or certifications to ensure your partners are also committed to reducing their carbon emissions.

Demanding Sustainable Materials and Components

Use your purchasing power to drive change. Prioritise suppliers that offer low-carbon materials, recycled content, and energy-efficient components. This sends a clear market signal that sustainability is a key factor in your procurement decisions.

Conclusion

Slashing your business’s carbon footprint in 2026 is an achievable and necessary goal. The journey begins with measurement, followed by strategic action in high-impact areas: optimising energy efficiency, transitioning to renewable energy, rethinking transportation, mastering waste reduction, and engaging your supply chain. These steps not only help mitigate climate change but also deliver tangible business benefits, including cost savings, enhanced brand value, and a more potent competitive edge. The time for incremental change is over. By implementing these simple yet powerful strategies, your business can become a leader in the transition to a sustainable, low-carbon economy.