When you think about inventory management in Australian logistics, it’s clear that optimising this aspect can significantly impact your operations. You’re likely aware that effective demand forecasting and strategic stock management can reduce costs and improve customer satisfaction. But how do you implement these strategies in a way that adapts to the unique challenges of the Australian market? As you investigate the various techniques and technologies available, you’ll uncover fundamental insights that can transform your approach and improve your bottom line. What’s the first step you should take to start this journey?

The Importance of Inventory Management

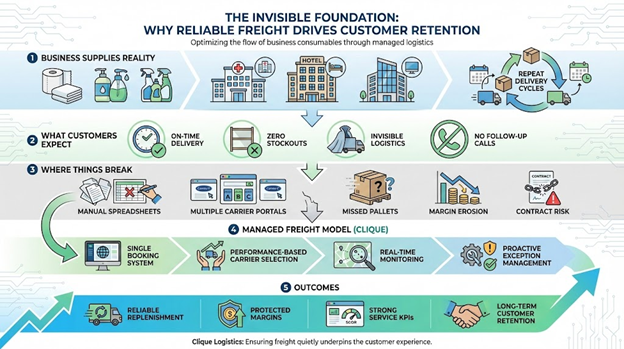

When it comes to running a successful business, you must pay attention to the importance of inventory management. Effective inventory management directly impacts customer satisfaction by ensuring that products are available when demand spikes, reducing the chances of stockouts.

By focusing on inventory turnover, you can streamline your stock replenishment processes, making your operations more efficient. Setting appropriate service level targets is vital, as higher service levels can lead to increased carrying costs. Striking a balance between satisfying your customers and managing costs is key.

Furthermore, recognising supply chain constraints, such as storage capacity and supplier limitations, allows you to develop realistic inventory strategies that improve profitability.

Embracing advanced technologies like AI and cloud-based solutions can further optimise inventory management in Australian logistics. These tools facilitate better tracking and forecasting, helping you to avoid overstock and understock situations.

By refining your approach to inventory management, you will improve your operational efficiency and create a more responsive supply chain that meets customer demands.

Effective inventory management is vital for nurturing lasting relationships with your customers and sustaining your business growth.

Demand Forecasting Techniques

Effective demand forecasting techniques are crucial for refining inventory management in Australian logistics. You can accurately predict future inventory needs by leveraging historical data and market trends. This foresight helps maintain ideal stock levels and reduces costs linked to overstocking or stockouts.

Statistical models, such as time series analysis and causal models, are crucial in enhancing the accuracy and reliability of your demand predictions. You can gain deeper insights into customer demand patterns and market behaviour by incorporating predictive analytics.

Furthermore, integrating advanced software solutions, including AI and machine learning, can significantly boost your forecasting capabilities. These technologies analyse vast datasets to deliver more precise predictions, allowing you to respond swiftly to changing market conditions.

When you implement robust demand forecasting techniques, you’ll notice improved inventory turnover rates. Aligning stock levels with actual consumer demand minimises waste and maximises profitability.

In addition, effective forecasting equips you to plan for seasonal trends and unexpected fluctuations, enhancing your overall responsiveness and agility within the supply chain. Adopt these techniques to refine your inventory management strategy and stay ahead in the competitive logistics environment.

Service Level Target Strategies

Setting service level targets is critical for optimising inventory management in Australian logistics. These targets define the standards for product availability, directly impacting customer satisfaction and driving sales and loyalty.

You need to balance higher targets with inventory carrying costs to achieve effective service level optimisation. While increased service levels can improve customer satisfaction, they require careful analysis to guarantee cost management isn’t compromised.

Utilising demand forecasting tools is vital for setting realistic service level targets. You can align your inventory with customer expectations and market trends by leveraging historical sales data.

It is important to regularly review and adjust these targets to keep pace with changing market dynamics and consumer behavior. This adaptability guarantees that your inventory management aligns with your business goals, maintaining a competitive edge.

Furthermore, the impact of service levels extends beyond stock levels; it influences supplier relationships and operational efficiencies.

Establishing clear service level strategies can improve your overall supply chain performance, leading to enhanced customer satisfaction while effectively managing costs.

Identifying Supply Chain Constraints

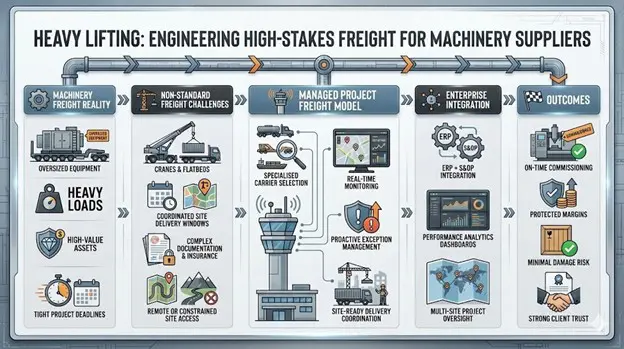

In identifying supply chain constraints, businesses must recognise various limitations that can hinder effective inventory management, such as storage capacity, budget restrictions, and supplier capabilities.

Conducting a thorough bottleneck analysis is vital for pinpointing where inefficiencies occur, allowing you to make dynamic adjustments that improve operational efficiency.

Start with a capacity assessment to understand your storage limitations and how they affect inventory levels. This will guide your resource allocation decisions.

Moreover, evaluating suppliers helps you gauge supplier capabilities and identify potential risks that could impact your supply chain.

Acknowledging operational constraints can help you develop inventory management plans that align with your financial resources and service level targets.

Cost considerations are significant; balancing inventory costs with performance metrics guarantees that you maintain customer satisfaction without overspending.

Adapting to Market Changes

Amidst the fast-paced evolution of consumer preferences, especially in e-commerce, you must be prepared to adapt your inventory management strategies. With 30% of consumers now expecting faster delivery options, your approach to market responsiveness is critical.

Utilise advanced technology like AI and machine learning to improve demand forecasting accuracy by up to 30%, helping you reduce overstock and stockout situations effectively.

Utilising real-time data analytics is another way to stay ahead of consumer trends. This allows you to respond to market dynamics with agility, improve operational efficiency, and potentially cut costs by 20%.

Pay close attention to seasonal trends, as historical sales data can help you anticipate demand fluctuations during peak periods like the holiday season, where sales may increase by over 50%.

Inventory Optimisation Best Practices

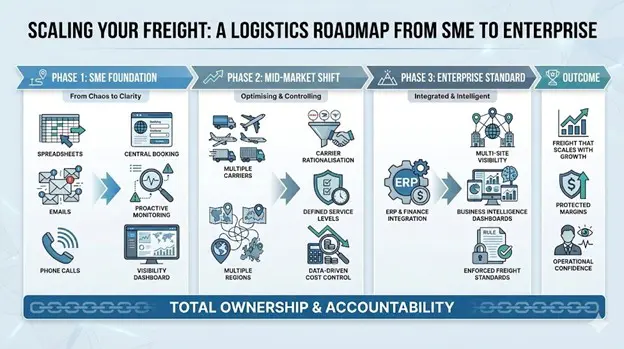

To optimise inventory management effectively, you must focus on implementing best practices that improve efficiency and reduce costs. Start using demand forecasting tools to minimise overstock and understock situations, potentially cutting these issues by up to 30%. This will help you maintain healthier inventory levels and better cash flow.

Incorporate safety stock strategies to balance customer satisfaction and cost management, ensuring you meet service level targets without incurring excessive carrying costs. Regularly analyse SKU performance; companies that do this can boost inventory turnover rates by as much as 20%, keeping high-demand products readily available.

Consider adopting technology for real-time inventory tracking. Businesses utilising automated systems often report a 50% reduction in manual errors, enhancing overall accuracy.

Finally, continuously evaluate your inventory levels and consider implementing just-in-time (JIT) practices. This approach can significantly cut holding costs, sometimes exceeding 25%, particularly in fast-paced markets.

Role of Technology in Management

Effective inventory optimisation sets the stage for leveraging technology in management. You can significantly reduce manual errors and boost order accuracy in your logistics operations by implementing real-time tracking.

Integrating AI and machine learning improves demand forecasting, helping you avoid overstock and stockouts. This means you can maintain ideal inventory levels, ensuring that you meet customer needs without excess waste.

Cloud solutions offer scalability and accessibility, allowing you to manage inventory seamlessly across multiple channels. Advanced inventory management software provides automated notifications when stock levels fall below a certain threshold, preventing supply chain disruptions.

Moreover, adopting IoT analytics gives you real-time data that empowers you to reach well-informed conclusions regarding stock levels and operational efficiencies.

By utilising these technologies, you gain unprecedented inventory visibility, enabling you to respond quickly to changing market conditions.

SKU Management and Distribution

Precision in SKU management is crucial for optimising inventory distribution in Australian logistics. By ensuring SKU synchronisation with your inventory systems, you can prevent overselling and maintain accurate real-time inventory levels. This accuracy improves operational efficiency, allowing you to respond swiftly to market demands.

Utilising data from historical order patterns helps you strategically distribute inventory closer to where it’s most needed. This approach reduces shipping costs and increases delivery times, keeping your customers satisfied.

Furthermore, inventory bundling for promotional activities should be considered. This tactic simplifies product management and boosts customer appeal, particularly during peak sales.

Implementing a centralised warehouse management system streamlines your operations, leading to faster order fulfilment.

Regularly analysing SKU performance and your inventory distribution strategies allows you to adapt quickly to changing market conditions. By staying proactive, you can optimise stock levels across your supply chain, always meeting customer expectations.

Benefits of Effective Inventory Strategies

A well-crafted inventory strategy offers significant advantages that can transform your logistics operations in Australia. You’ll improve cash flow by minimising excess stock and enhancing liquidity by implementing effective inventory management techniques. This operational efficiency is crucial in today’s competitive market.

Accurate demand forecasting tools help reduce overstock and stockouts, improving customer satisfaction and timely order fulfilment—key elements for boosting customer retention.

Utilising just-in-time (JIT) inventory practices can lead to cost reduction by lowering holding costs and optimising storage space for high-demand products. This streamlines your logistics operations and renders your supply chain more agile.

Furthermore, employing robust inventory management systems allows for real-time tracking and analytics, which helps you make educated choices that improve overall efficiency and reduce manual errors.

Collaborating with third-party logistics (3PL) providers can further strengthen your inventory strategies. You can achieve faster delivery times and improve supply chain performance by leveraging their advanced technology and expertise.

In short, effective inventory strategies drive operational success and solidify your competitive edge in the Australian logistics environment.

Challenges in Inventory Management

Numerous challenges in inventory management can hinder your logistics operations in Australia. One major issue is demand variability, which can lead to stockouts or overstock situations. To combat this, you must implement effective forecasting techniques that align your inventory levels with consumer behaviour.

Furthermore, supply chain disruptions—whether from natural disasters or global events—can affect inventory availability and delivery schedules. Adopting agile inventory management practices is fundamental for managing these uncertainties.

Integrating new technology into your inventory management system can likewise pose challenges. The complexity and time required to train staff and guarantee smooth transitions can hinder progress.

In addition, finding the right balance between inventory costs and product availability is imperative. You’ll need sophisticated overstock strategies to manage cash flow effectively while preventing stockouts.

Lastly, maintaining accurate inventory records is critical. Data inaccuracies can lead to inefficiencies, mismanaged stock levels, and reduced customer satisfaction.

Conclusion

Optimising inventory management in Australian logistics is essential for your business’s success. Implementing effective strategies and leveraging advanced technologies can improve demand forecasting, streamline stock replenishment, and adapt to market changes. Regularly evaluating supply chain constraints will help you stay aligned with customer expectations. Adopt these practices to improve your operational efficiency, reduce costs, and ultimately boost customer satisfaction, ensuring your logistics operations thrive in a competitive environment.