The modern supply chain operates on a promise: rapid, reliable, and transparent delivery. Yet this promise is under threat from a growing, systemic challenge: a critical labour shortage. Across warehouses, distribution centres, and on the road, the logistics industry is grappling with an unprecedented workforce gap. This gap, widened by demographic shifts and surging customer demand, is causing delivery delays, increasing operational costs, and straining the very foundation of global commerce.

Simply hiring more people is no longer a sustainable solution. The path forward requires a more intelligent, integrated approach. The solution lies in the powerful synergy between innovative technology and strategic partnerships. By leveraging automation, advanced analytics, and the expertise of orchestrators like Clique, businesses can not only mitigate labour shortages but also build a more resilient, efficient, and future-proof supply chain. This article explores how this dual strategy is essential for keeping freight moving seamlessly in an increasingly complex world.

The Growing Freight Challenge: Navigating Unprecedented Labour Shortages

The pressure on the global supply chain has never been greater. At the heart of this pressure is a deepening labour crisis that impacts every node of the network, from the first mile to the last. Understanding the scope and consequences of this shortage is the first step toward building effective, long-term solutions.

The Critical State of the Logistics Workforce

The logistics workforce shortage is not a temporary trend but a structural problem with deep roots. An ageing population of drivers and warehouse staff is retiring faster than new talent can be recruited to replace them. Recent industry reports highlight the severity, with surveys indicating that more than 76% of supply chain leaders report significant labour shortages. A perception problem compounds this skills gap; logistics careers are often seen as physically demanding with limited flexibility, making it difficult to attract a new generation of workers. As e-commerce continues to drive customer demand for faster fulfilment, the available pool of skilled labour is simply insufficient to keep pace, creating a bottleneck that technology and new strategies must address.

Economic and Operational Ramifications

The consequences of these labour shortages ripple throughout the economy. For logistics companies, the immediate impact is a sharp rise in operational costs due to higher wages, recruitment expenses, and overtime pay needed to cover gaps. This financial strain is passed down the supply chain, ultimately affecting consumer prices. Operationally, a lack of staff results in slower order fulfilment, higher error rates, and underutilised assets in warehouses and distribution centres. Shipments are delayed, delivery windows are missed, and overall supply chain reliability deteriorates. This directly erodes customer satisfaction and can irreparably damage a brand’s reputation in a market where speed and reliability are paramount.

Innovative Technology: The Foundation for Resilient Freight Movement

While labour shortages present a formidable challenge, they also serve as a powerful catalyst for technological innovation. Smart technology is no longer a luxury but a fundamental necessity for survival and growth in the logistics industry. From intelligent software to autonomous robotics, these tools are creating a more efficient, predictable, and resilient operational backbone.

Enhancing Visibility and Predictive Power

The “brains” of the modern supply chain are sophisticated data-driven software platforms. Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) provide real-time visibility into inventory and shipments, allowing for more agile decision-making. However, the true game-changer is the integration of predictive analytics. This technology analyses historical data, market trends, and external factors such as weather to forecast customer demand with remarkable accuracy. Advanced analytics goes a step further, enabling proactive risk management by identifying potential disruptions before they occur. This allows logistics managers to optimise routes, reallocate resources, and manage inventory preemptively, ensuring smoother operations with a leaner workforce.

Revolutionising Warehouse Operations with Automation

Within the four walls of warehouses and distribution centres, automation and robotics are directly addressing the physical labour gap. Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) navigate floors to transport goods, dramatically reducing the need for manual material handling. Robotic arms can pick, sort, and palletise items with speed and precision far exceeding human capabilities. These systems work tirelessly, minimise errors in order fulfilment, and create a safer work environment by taking over repetitive and physically strenuous tasks. By automating these key processes, companies can significantly increase throughput and efficiency without a proportional increase in headcount.

Powering Intelligent Transportation and Delivery

Technology’s impact extends beyond the warehouse to the open road. Advanced software optimises delivery routes in real time, factoring in traffic, delivery windows, and vehicle capacity to ensure maximum efficiency for last-mile deliveries. Looking ahead, emerging technologies promise even greater transformation. Drones are being tested in various pilots for delivering small packages to remote or congested areas. Similarly, autonomous vehicles are undergoing extensive trials and have the potential to revolutionise long-haul freight by operating around the clock. While widespread adoption faces regulatory hurdles, these innovations signal a future where transportation is less dependent on a shrinking pool of human pilots and drivers.

The Strategic Advantage: How Partners Like Clique Orchestrate Seamlessness

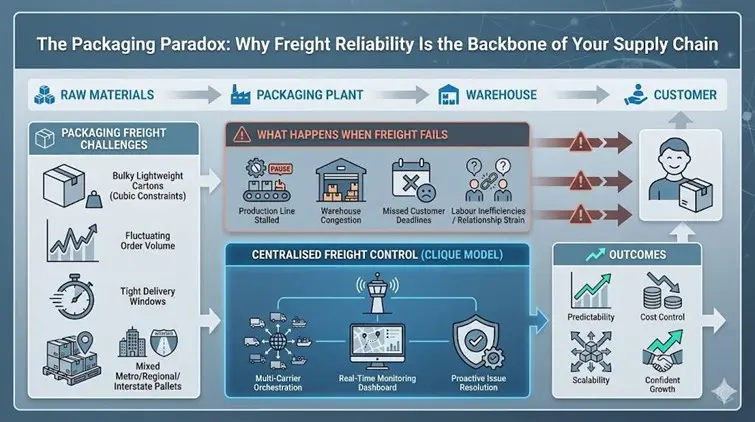

Technology alone is not a panacea. Implementing a disparate collection of software and robotics without a coherent strategy can lead to integration challenges and underwhelming results. This is where strategic partners like Clique provide a critical advantage, acting as orchestrators who harmonise technology, processes, and people to create a truly seamless supply chain.

Building a Network of Unwavering Supply Chain Resilience

A key weakness exposed by labour shortages is over-reliance on a single channel or carrier. A strategic partner like Clique builds resilience by developing a diversified, multi-carrier network. This approach provides crucial flexibility and capacity, especially during peak seasons or unexpected disruptions. If one carrier faces a local labor shortage or service interruption, freight can be seamlessly rerouted through another part of the network. This networked model acts as a vital buffer, ensuring shipments continue to move reliably despite isolated pressures on the workforce.

Beyond Technology: Clique as a Digital Transformation Catalyst

Adopting new technology can be daunting. A partner like Clique serves as a digital transformation catalyst, guiding businesses through the complexities of selecting, implementing, and integrating the right tools. This goes beyond simply selling a piece of software. It involves analysing a company’s unique operational challenges, identifying the most impactful technologies—from predictive analytics to warehouse automation—and ensuring they are integrated smoothly with existing systems. This expert guidance helps businesses avoid costly mistakes and accelerates their return on investment, ensuring technology empowers rather than overwhelms their operations.

Customised Solutions for Diverse Logistics Industry Needs

The logistics industry is not monolithic; the needs of a retail e-commerce business differ vastly from those of a B2B industrial manufacturer. A one-size-fits-all approach to technology and logistics is bound to fail. Strategic partners excel at developing customised solutions. By understanding a business’s specific pain points—whether it’s managing complex last-mile delivery or optimising inbound materials flow—a partner like Clique can tailor a unique combination of technology, carrier networks, and operational strategies. This bespoke approach ensures that solutions are directly aligned with business goals and effectively address the most pressing challenges.

The Synergy: Where Smart Tech Meets Strategic Partnership for Uninterrupted Flow

The most powerful outcomes emerge when innovative technology and strategic partnership are not viewed as separate solutions but as two halves of a whole. Their synergy creates a resilient ecosystem in which a reduced workforce can deliver greater results, problems are solved proactively, and capacity is maximised.

Bridging the Skills Gap with Integrated Solutions

One of the most significant benefits of modern logistics software and automation is its user-centric design. Intuitive interfaces and simplified workflows lower the barrier to entry, making it easier and faster to train new employees. A strategic partner helps select and implement these integrated solutions, ensuring technology bridges the existing skills gap. By making complex tasks more manageable, these systems empower a less experienced workforce to operate at a high level of proficiency, effectively expanding the available talent pool.

Proactive Problem Solving and Scenario Planning

A reactive supply chain is always one step behind. The combination of advanced analytics and partner expertise enables a shift to proactive problem-solving. A partner like Clique can leverage data to run scenario-planning models that simulate the impact of potential disruptions, such as a port closure, a carrier strike, or a sudden spike in customer demand. This foresight enables the development of contingency plans, ensuring the supply chain can adapt swiftly and effectively, maintaining uninterrupted flow even in the face of unforeseen challenges.

Enhancing Efficiency and Maximising Capacity

Ultimately, the goal is to do more with less. Innovative technology, such as route optimisation software, ensures every vehicle is used to its full potential. Warehouse automation increases the speed and volume of order fulfilment within the same physical footprint. A strategic partner amplifies these gains by managing a flexible carrier network and accessing additional capacity when needed. This synergy ensures that every asset—from the warehouse floor to the delivery truck—is maximised, squeezing out inefficiencies and boosting overall productivity.

Beyond Addressing Shortages: Elevating the Customer Experience

Solving labor shortages is a critical operational goal, but the ultimate measure of success is its impact on the end customer. The integration of smart technology and strategic partnerships does more than just keep freight moving; it fundamentally enhances the customer experience, building loyalty and driving growth.

Delivering on Customer Satisfaction Promises

Today’s customers expect speed, accuracy, and transparency. The efficiencies gained through automation and predictive analytics translate directly into a better customer experience. Automated order fulfilment reduces picking errors and processing times, while optimised routing ensures faster, more reliable last-mile delivery. Real-time tracking, powered by integrated software, provides the visibility customers now demand. By consistently meeting and exceeding these expectations, businesses can build a reputation for reliability that fosters deep customer satisfaction and long-term loyalty.

Fostering Sustainability and Eco-friendly Practices

Modern consumers and regulators are increasingly focused on environmental impact. Smart logistics offers a path to greater sustainability. Advanced analytics and route optimisation software help consolidate shipments and minimise miles travelled, significantly reducing fuel consumption and carbon emissions. A partner can further this goal by helping businesses select carriers with green initiatives or by optimising distribution networks to reduce the overall environmental footprint. These eco-friendly practices not only meet regulatory requirements but also enhance brand reputation among environmentally conscious consumers.

The Human Element: Empowering the Future Workforce in a Tech-Driven World

The narrative of technology in logistics is not one of replacement, but of collaboration. The goal is not to create a workforce of robots, but to empower a human workforce with robotic tools. This human-centric approach is key to building a sustainable and engaged talent pipeline for the future.

Upskilling and Reskilling for Tomorrow’s Logistics

As automation handles repetitive manual tasks, new, more skilled roles are emerging. The logistics workforce of the future will include robotics technicians, data analysts, and AI system managers. A forward-thinking approach involves investing in upskilling and reskilling programs to prepare the current workforce for these new responsibilities. This creates clear career progression paths, transforming logistics jobs into tech-focused careers and making the industry more attractive to new talent.

Collaborative Work Stations and Ergonomics

Innovative technology can significantly improve the quality of the work environment. Robotics can take over the most physically demanding and injury-prone tasks, such as heavy lifting and repetitive movements. This creates safer, more ergonomic collaborative work stations where human employees can focus on tasks requiring judgment, problem-solving, and quality control. This not only reduces workplace injuries but also improves job satisfaction and employee retention—a critical advantage in a tight labour market.

Conclusion: A Seamless Future for Freight Through Intelligent Integration

The challenge of labour shortages in the logistics industry is undeniable, but it is not insurmountable. It forces a necessary evolution away from traditional, labour-intensive models toward a future that is smarter, more resilient, and deeply integrated. The path forward is clear: a strategic fusion of intelligent technology and expert partnership is the definitive solution to keeping the global supply chain moving seamlessly.

Reaffirming Clique’s Role as the Orchestrator of Progress

In this new landscape, the value of a strategic orchestrator like Clique cannot be overstated. Technology provides the tools, but a partner offers the wisdom, strategy, and network to deploy those tools effectively. Clique acts as the central nervous system, connecting disparate technologies, managing complex carrier relationships, and translating raw data into actionable intelligence. This role as a catalyst for digital transformation empowers businesses not only to survive current workforce challenges but also to thrive by building a truly agile and responsive supply chain.

The Promise of a Resilient, Efficient, and Seamless Logistics Industry

By embracing this dual approach, the logistics industry can transform a crisis into an opportunity. It is an opportunity to build a supply chain that is not only more efficient but also more sustainable and more humane. It promises a future where a highly skilled workforce, augmented by automation and guided by predictive analytics, delivers a superior customer experience. This is the promise of a seamless logistics industry—one that is resilient by design, efficient in practice, and prepared for tomorrow’s challenges.